Caterpillar Excavator Bolted Flag Removal Procedure and Installation Procedure

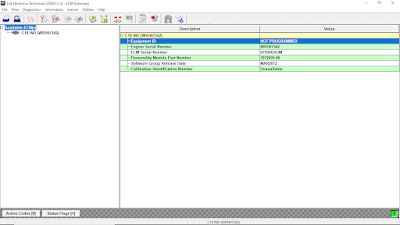

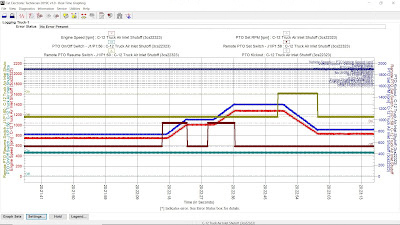

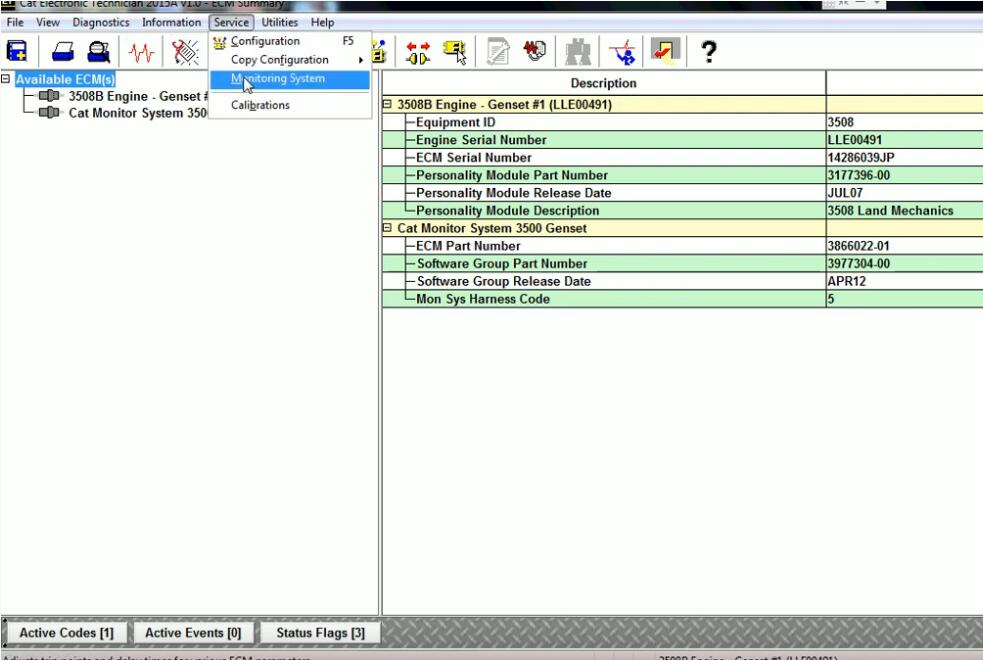

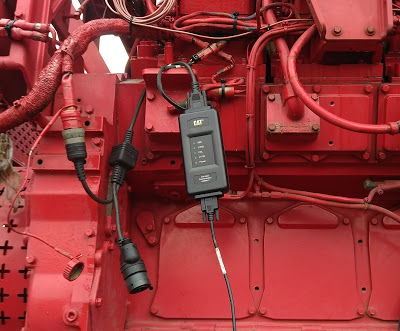

cat 325FLExcavator Bolted Flag RemovalProcedure and Caterpillar CAT Factory Password Calculator Generator 10 Digits VM Version Installation Procedure WARNING! Failure to follow the instruction below […]