How to change the BMW ICOM ISTA-D ISTA-P Language

BMW ICOM are with multi-language,if you want to change the language,pls let us know when you make the order,or default be english. If you want […]

BMW ICOM are with multi-language,if you want to change the language,pls let us know when you make the order,or default be english. If you want […]

V2023.03 Newest Version BMW ICOM Software ISTA-D ISTA 4.39.31 ISTA-P 3.71.0.200 with Engineer Programming Software Version : V2023.03 ISTA – D: 4.39.31 with SDP Programming […]

Q: Can BMW ICOM work with Rolls-Royce? A: yes, it can do, and no need to buy additional software. Q: I have BMW ICOM hardware from […]

Dear friends, goods news ,BMW ICOM updated the new software to 2022.03. V2022.03 BMW ICOM Engineers Software HDD For BMW ICOM Next BMW ICOM A2 A3 Diagnosis […]

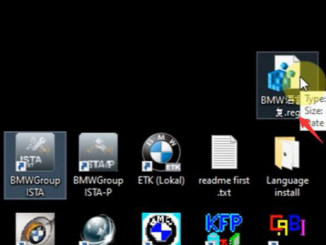

How to program BMW E-sys 1.Connect to BMW car; 2.Read FA,read ecu and Calculate ecu version.(Calculate will take 10 minutes) 3.Select SVT (calculated) 4.Select the […]

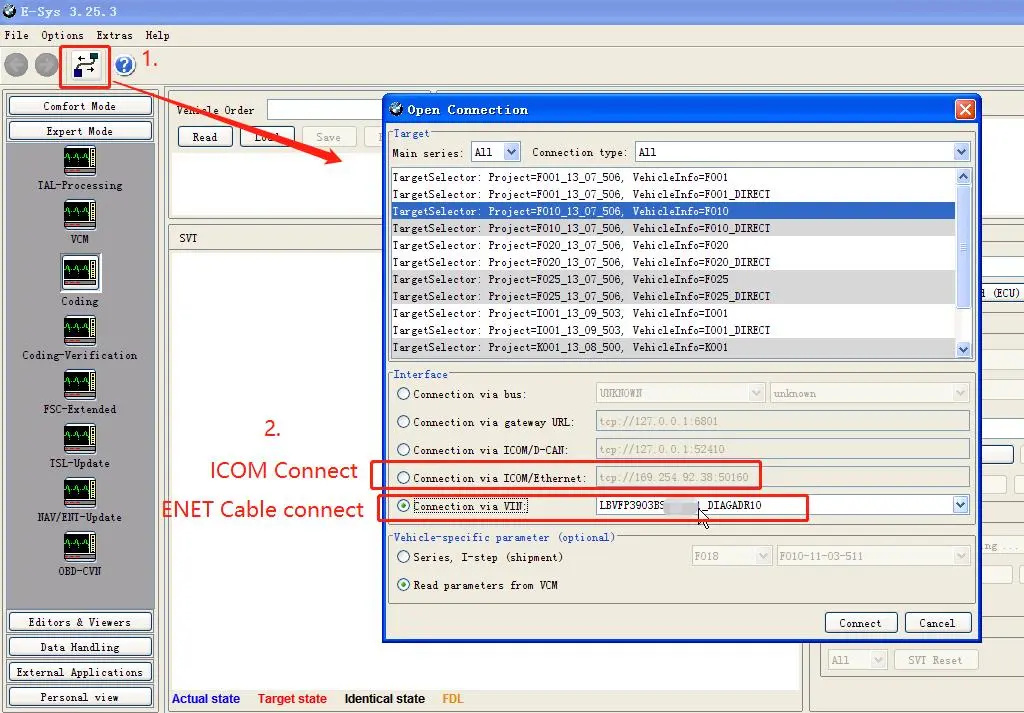

How to change the IP address of ENET WIFI 1.PC WIFI connect to ENET WIFI,(BMW ENET WIFI) WIFI name:ENET_WIFI_XXXX WIFI Password:12346578 2.Use the IP address […]

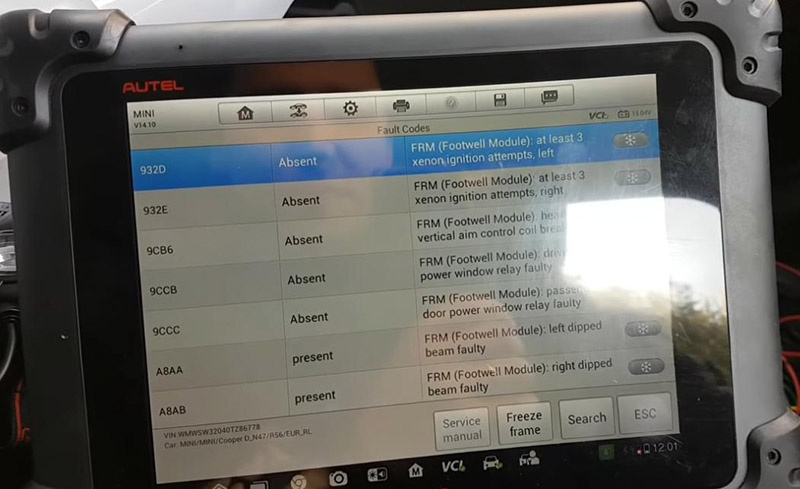

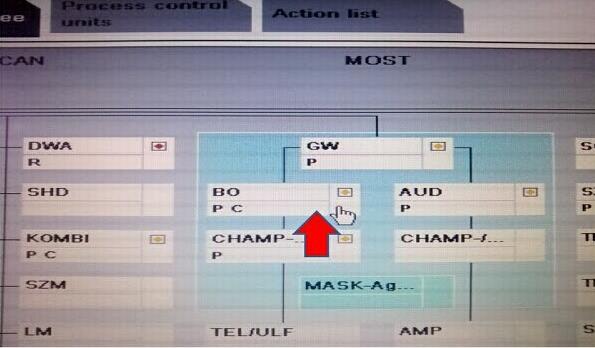

Purpose: To repair a BMW/MiniFRM module with corrupted data usually caused by low voltage. Now the FRM module won’t response, and electric windows don’t work. […]

BMW ICOM NEXT Latest Generation Diagnostic Head For BMW, MINI, Rolls-Royce BMW-Model. Can Replace BMW ICOM A2, including all function of ICOM A2. BMW ICOM […]

Does anyone have a solution for BMW ICOM Ista+ Programming Expert Mode? No expert mode available yet for ISTA+ v4.11.12. This will be an issue in […]

Latest ISTA BMW software with ISTA D:4.30.40 and ISTA P:3.68.0.0008 support diagnosis, coding and programming for BMW till 2021. Full Comprehensive professional dealer system for […]

Copyright © 2024 | WordPress Theme by MH Themes