CG FC-200 is arriving after 3-5 working days delivery on schedule, it will be used for ECU /EGS ECU clone, it is claimed to cover 4200 kinds of ECU and 80% of the models on the market. And it is claimed to be capable of data processing, module cloning, disassembly matching, DTC shielding, Immobilizer closed, ISN acquisition, Vin modification etc. If it is as good as promised? Read the following parts.

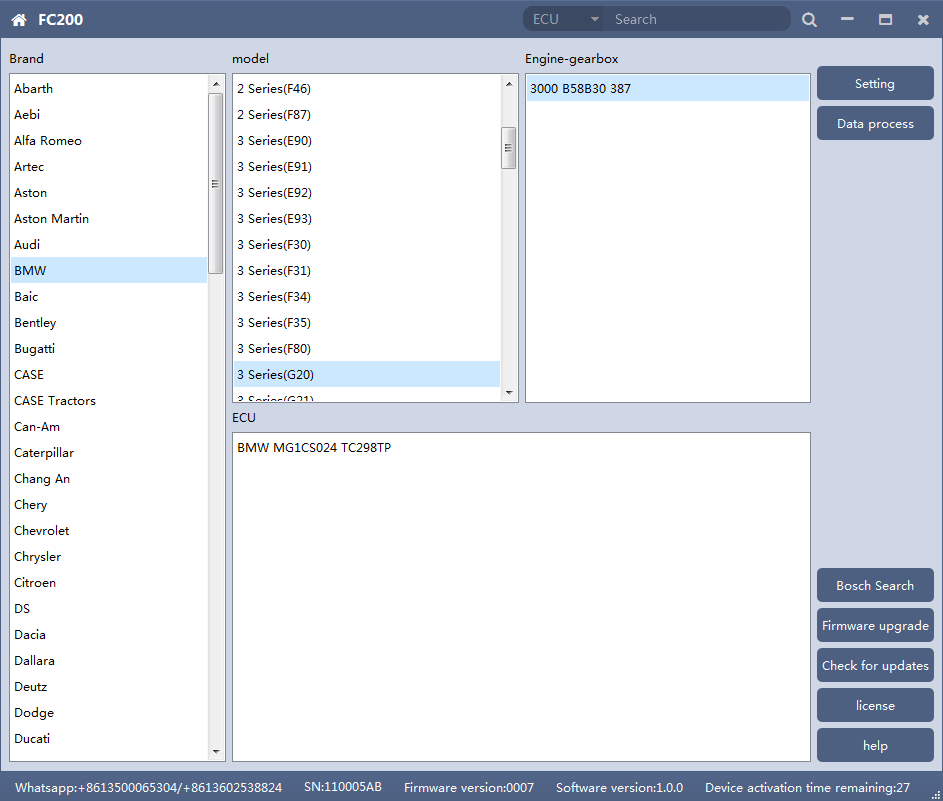

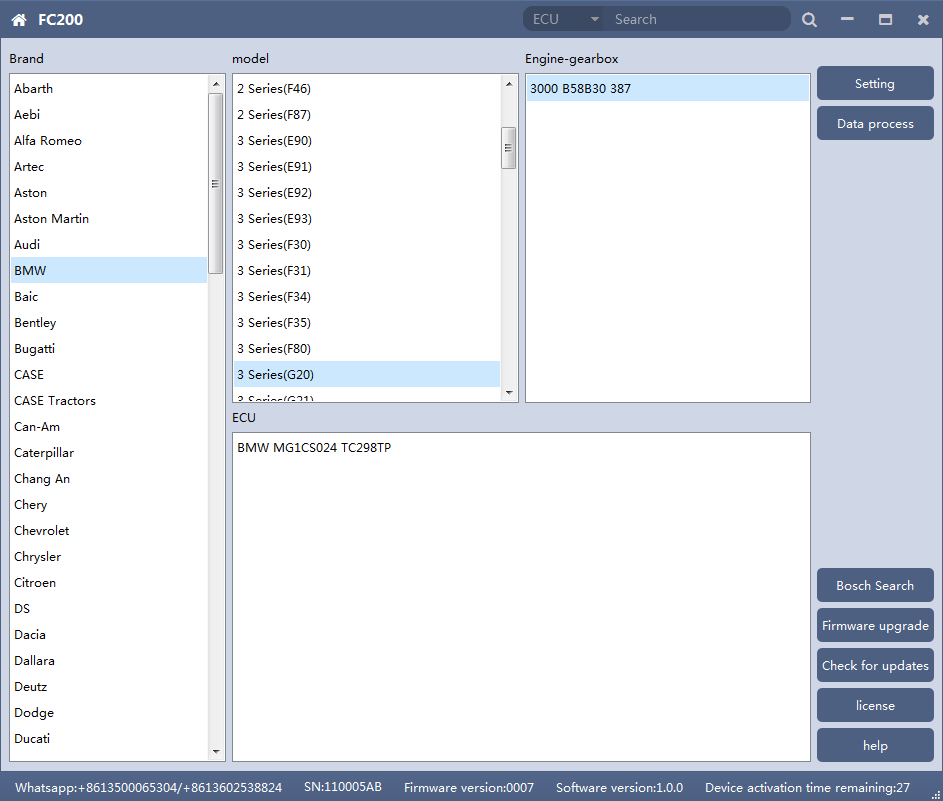

1. Software Use

Below the main interface is the software version and device information.

The functions on right side are are:

◎Setting Set the language, font size and display type.

◎Firmware update Firmware version update

◎Authorization info FC200 software requires authorization before use

◎Use help Open use document

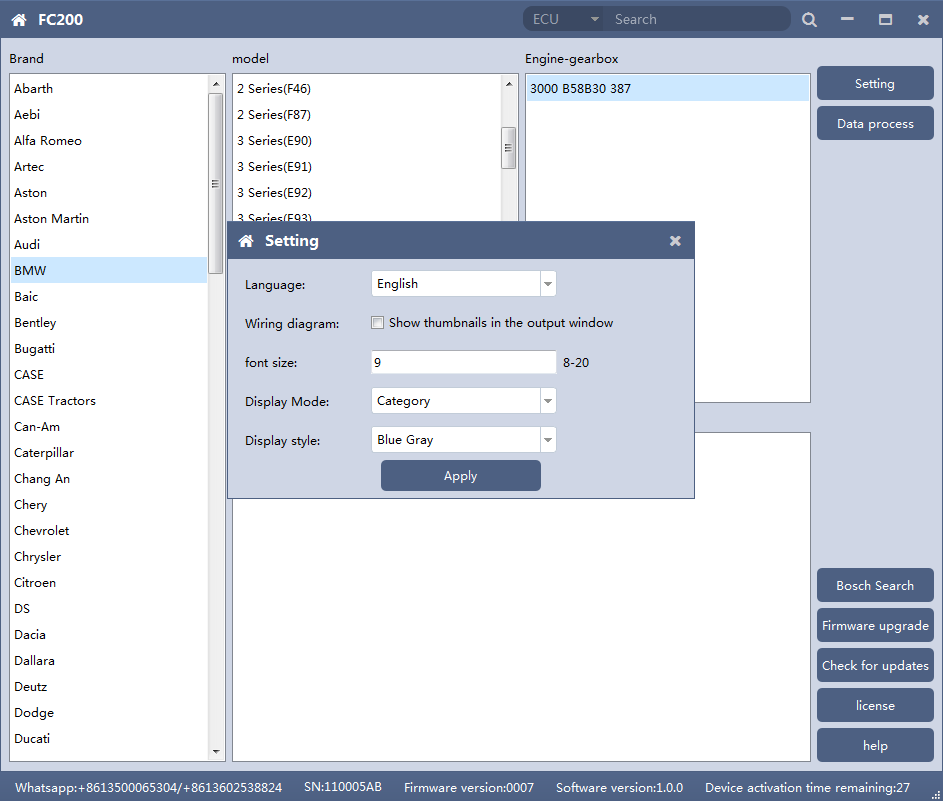

1. Setting

◎Language: Switch languages, currently supports Simplified Chinese, Traditional Chinese, English, French ,Polish and Spanish

◎Font size: You can enter the font size yourself (the larger the number, the larger the font) Range: 8-20

◎Display Method: Select category display and merge display

◎Display style: Blue gray and dark blue

1.1 Display Method

◎Select category display

◎Select category display

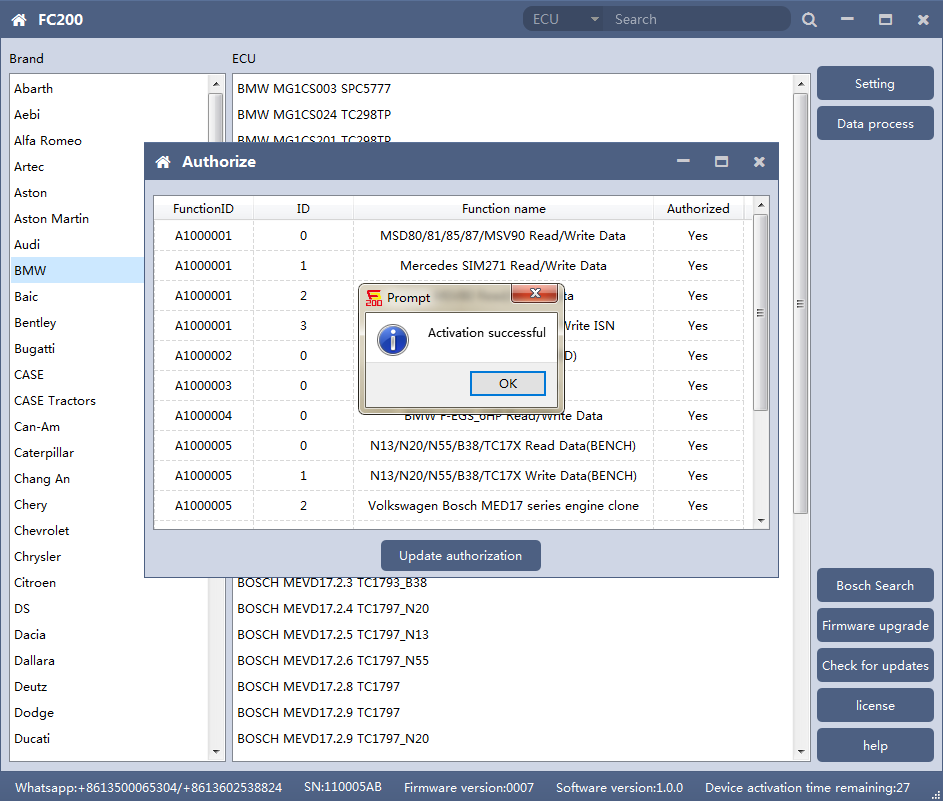

2. Device Authorization

◎FC200 software requires authorization before use

◎Click Authorization Information button on the main interface to view the authorization list

◎Click the Update Authorization button

◎If “No” is still displayed after updating authorization, please contact the manufacturer

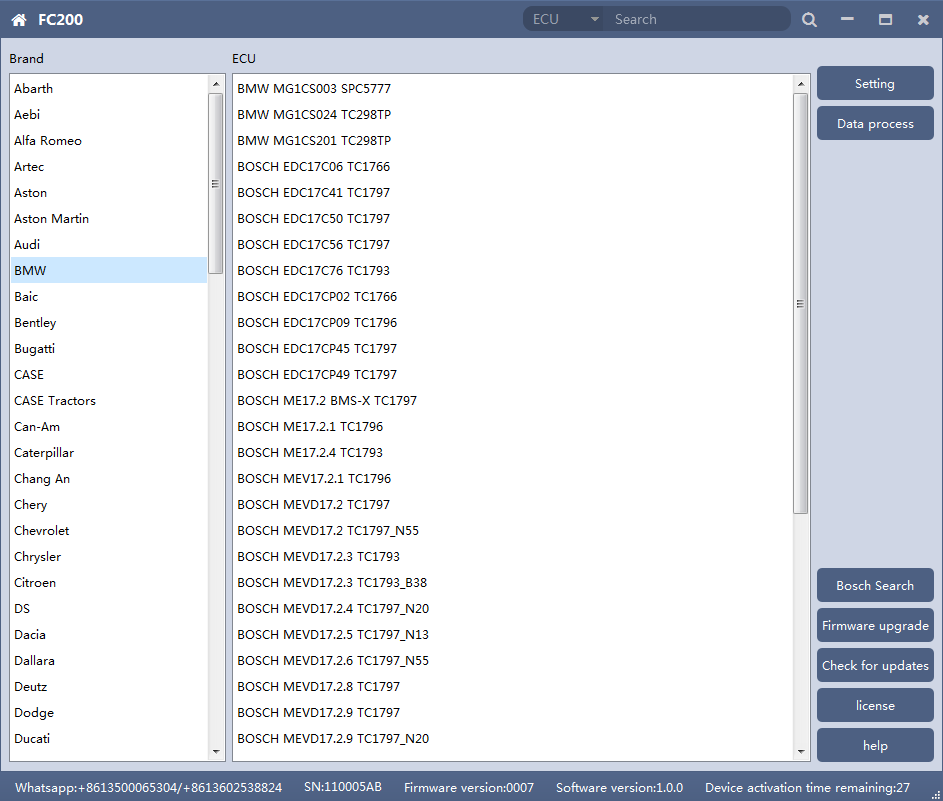

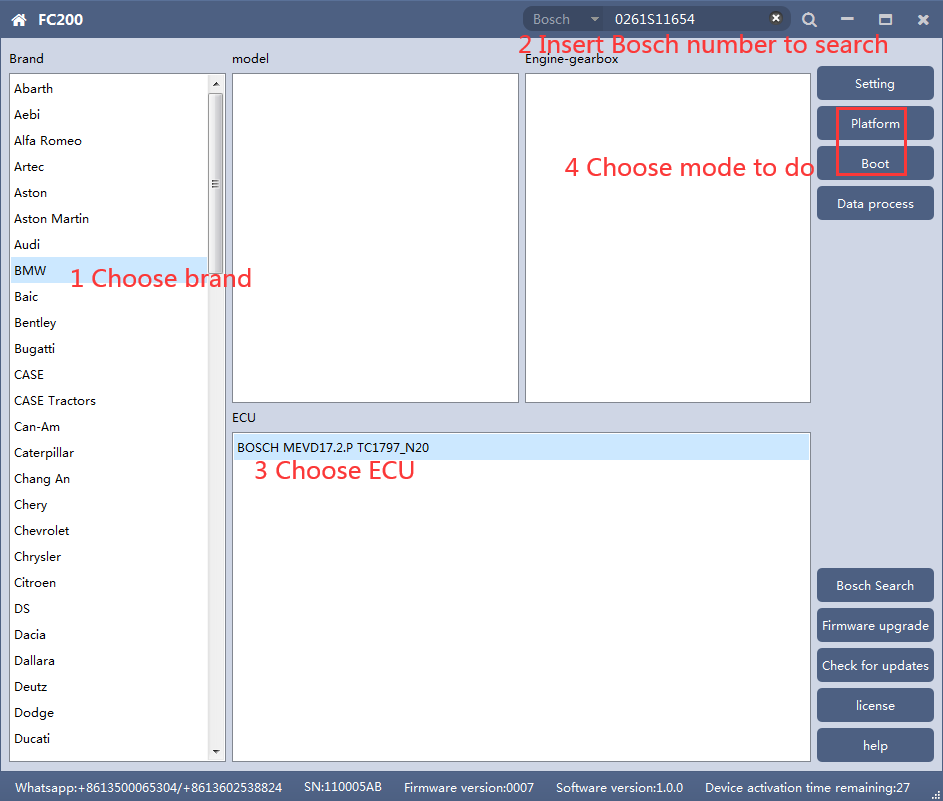

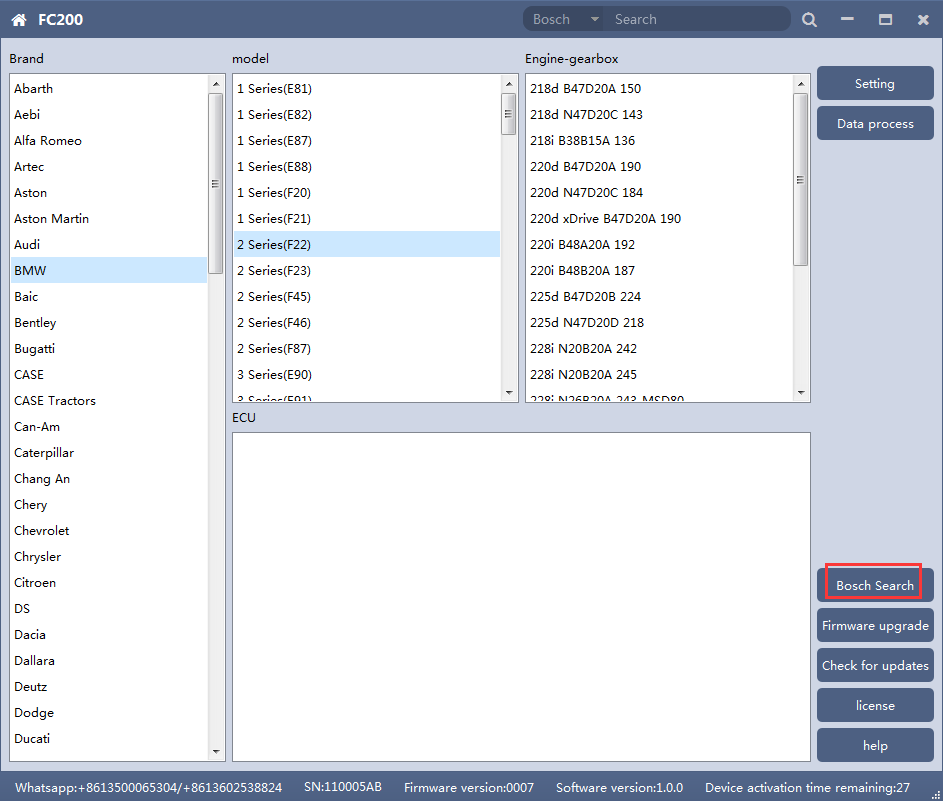

3. Device search function (frequently-used)

◎ECU search

◎Bosch number search

◎Bosch number query (click “Bosch search”)

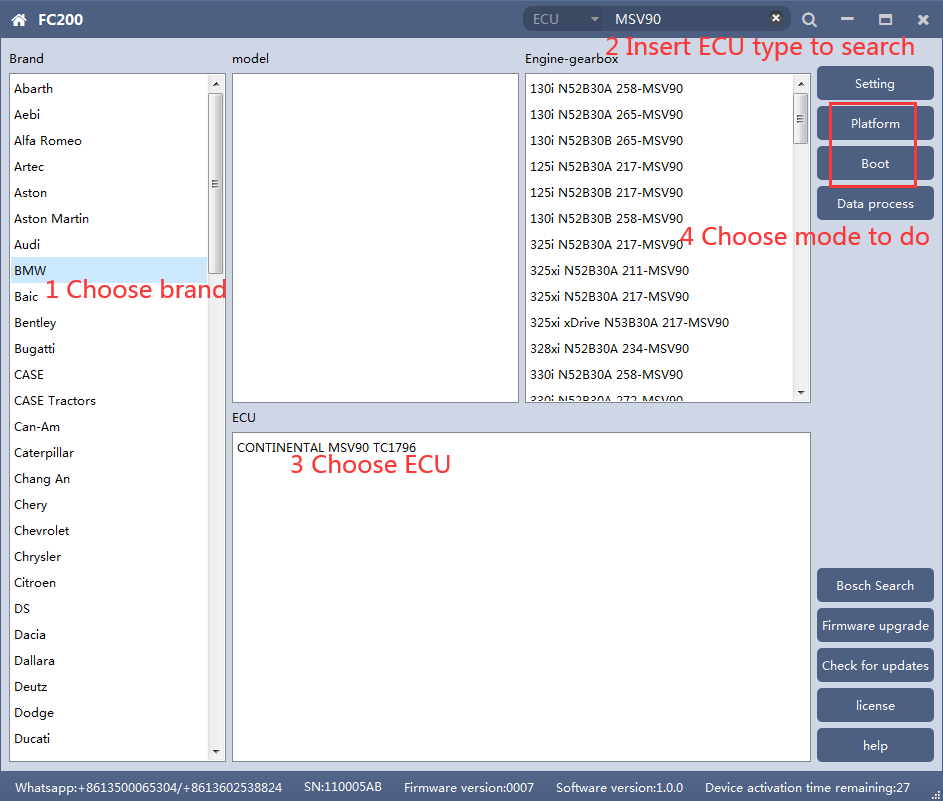

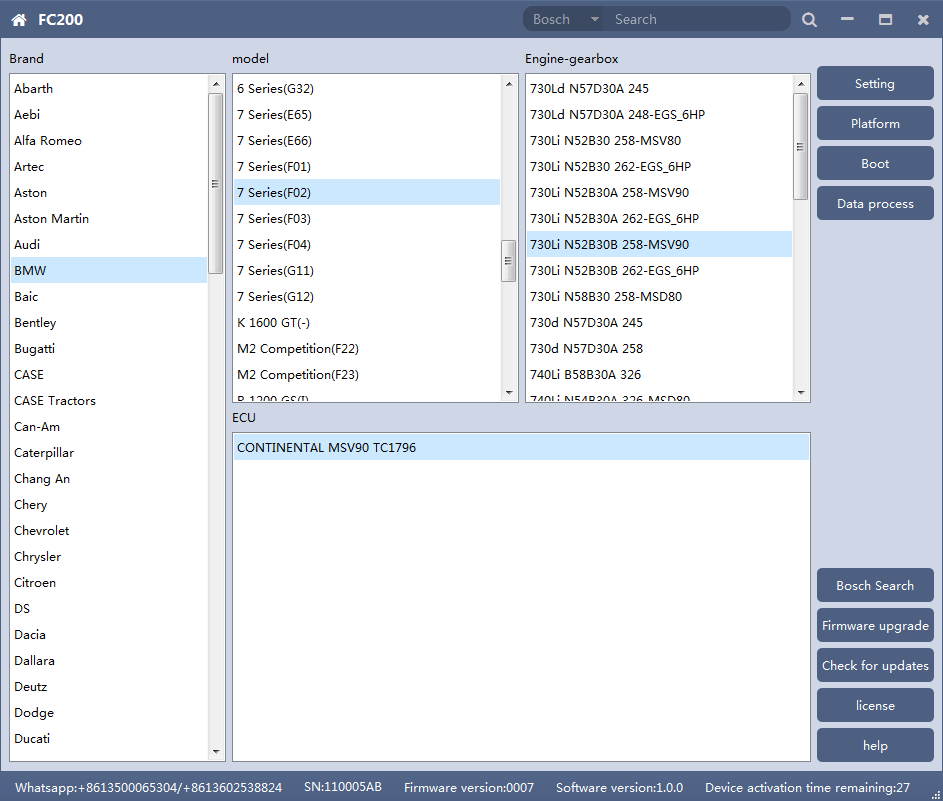

2. MSV90/80/MSD87/85/ 81/80/SIM271

FC200 currently supports the cloning and ISN reading of BMW models MSV90/80/MSD87/85/81/80 (E series, F series) and Mercedes-Benz SIM271 ECU.

1. Determine the type of ECU according to the vehicle model, and select the correct model, otherwise the normal operation will not be possible.The MSV90 is used for description below.

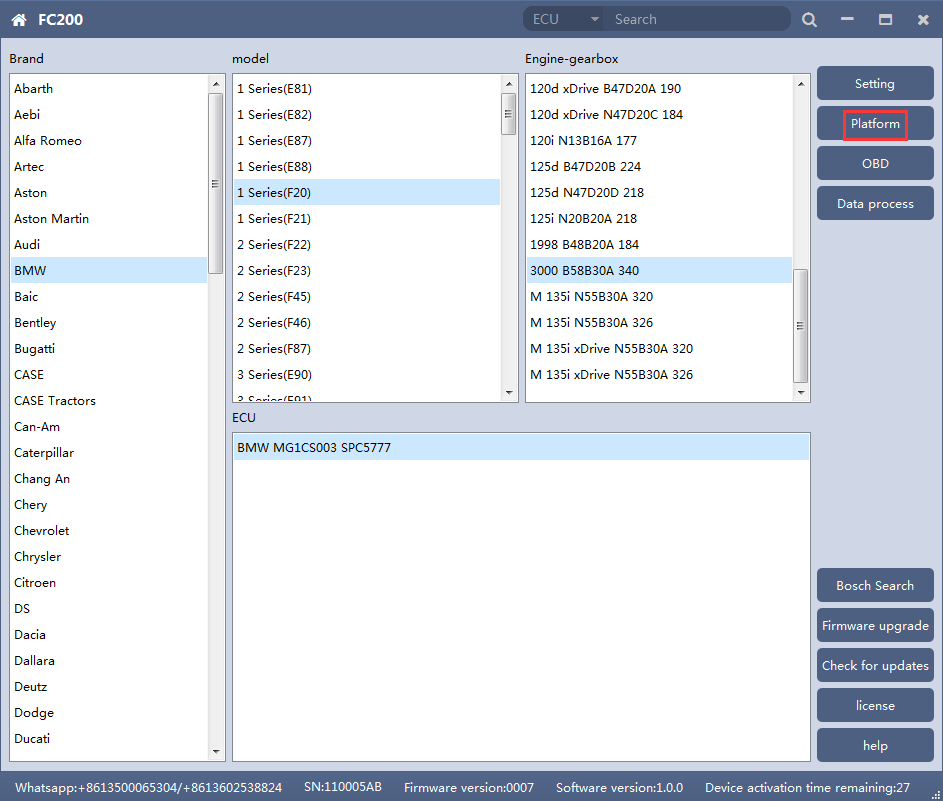

After selecting the correct ECU model, the “Platform” button will appear on the right. As shown in the figure above, click the “Platform” button to enter the ECU operation interface.

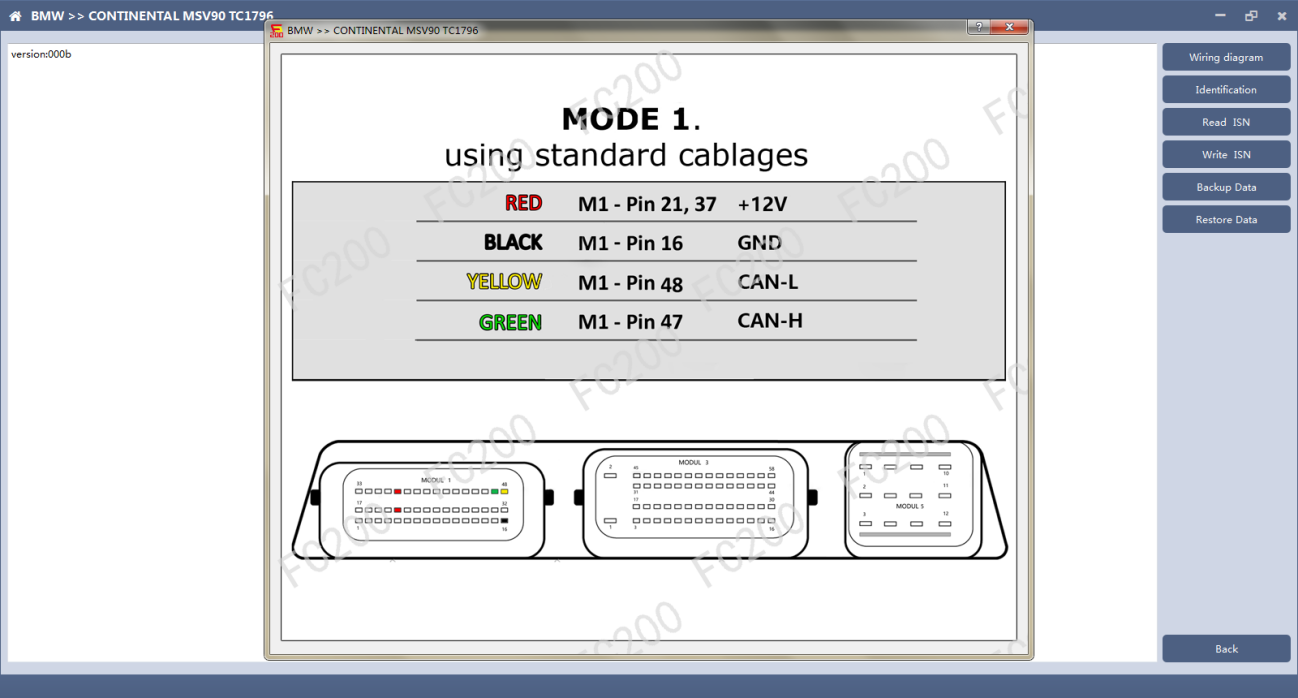

2. View wiring diagram

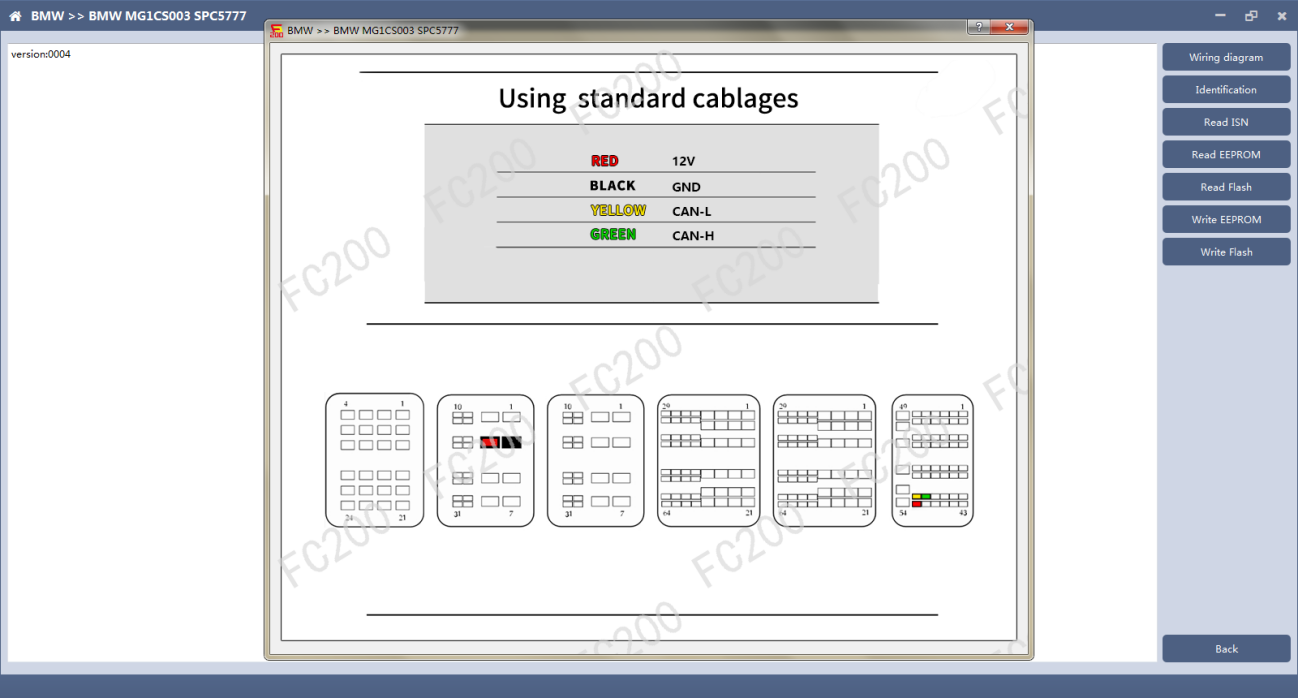

Click the “Wiring Diagram” button to view the ECU wiring diagram, connect the wiring harness correctly according to the wiring diagram, and connect with the device, plug in the device DC12V interface with 12V power supply.

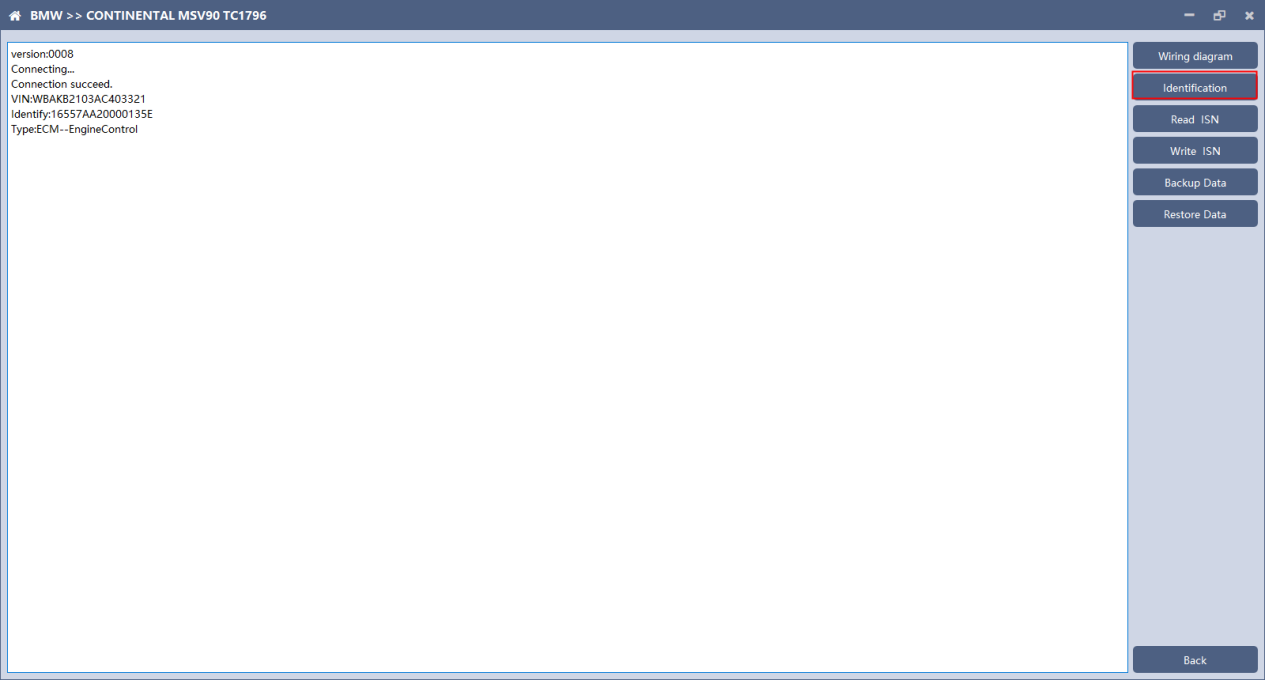

3. Identifying the ECU

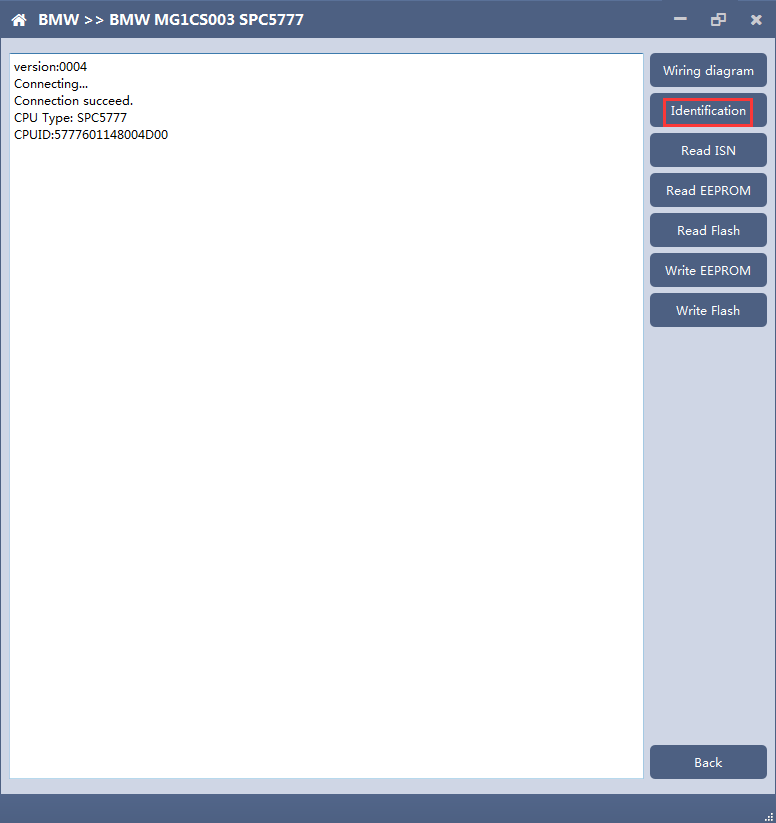

Click the “Identify” button to read the ECU related information, as shown in the figure above.

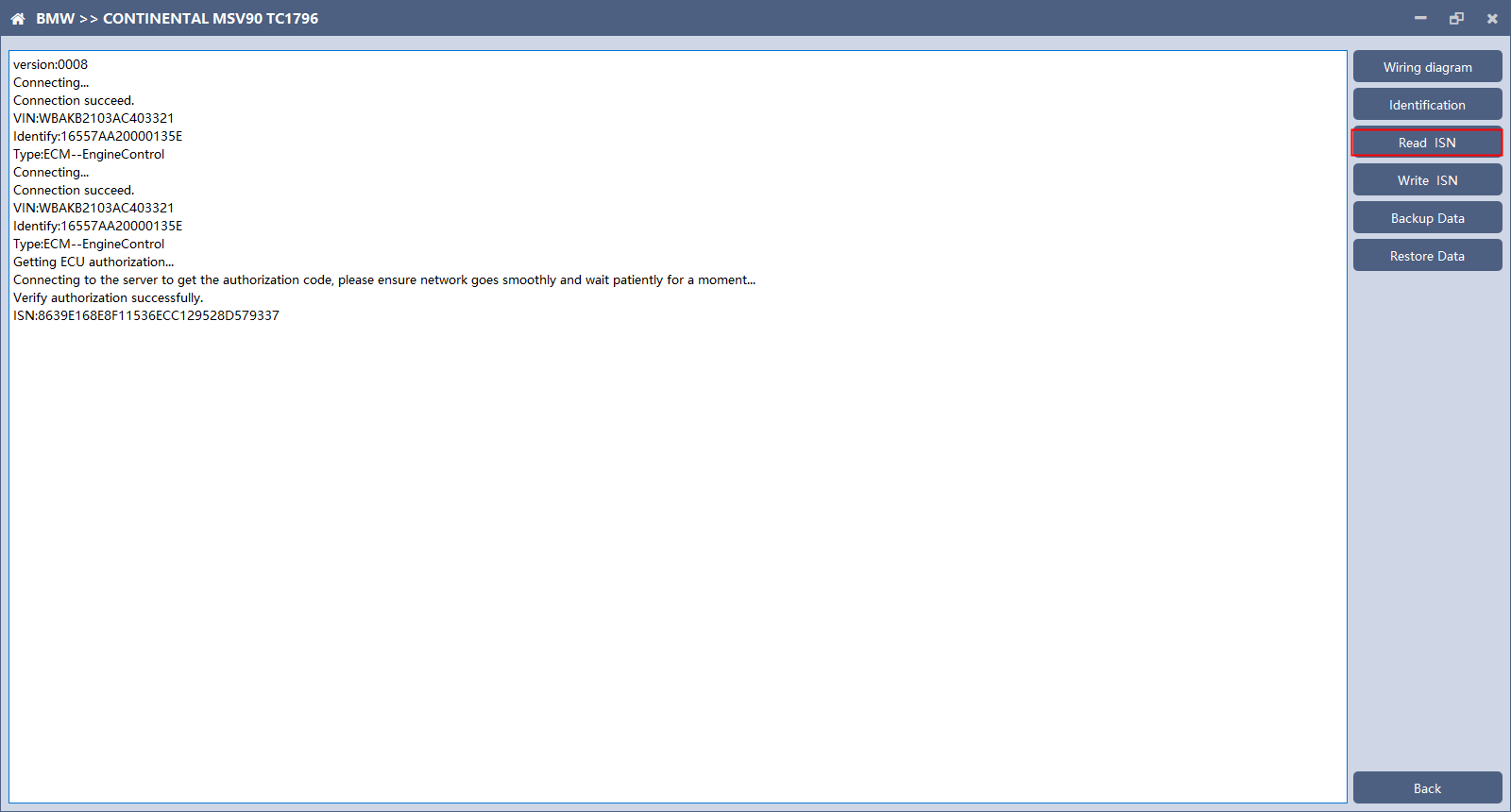

4. Reading ISN

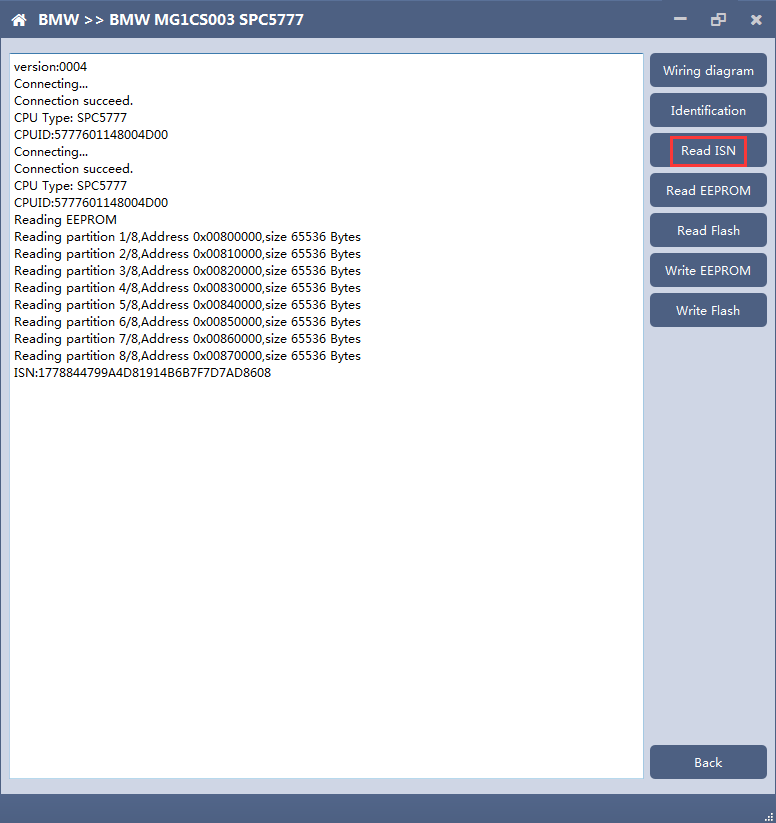

Click the “Read ISN” button to read the ISN.

Note: This operation needs to be connected to the network. Please ensure that the network is normal during using.

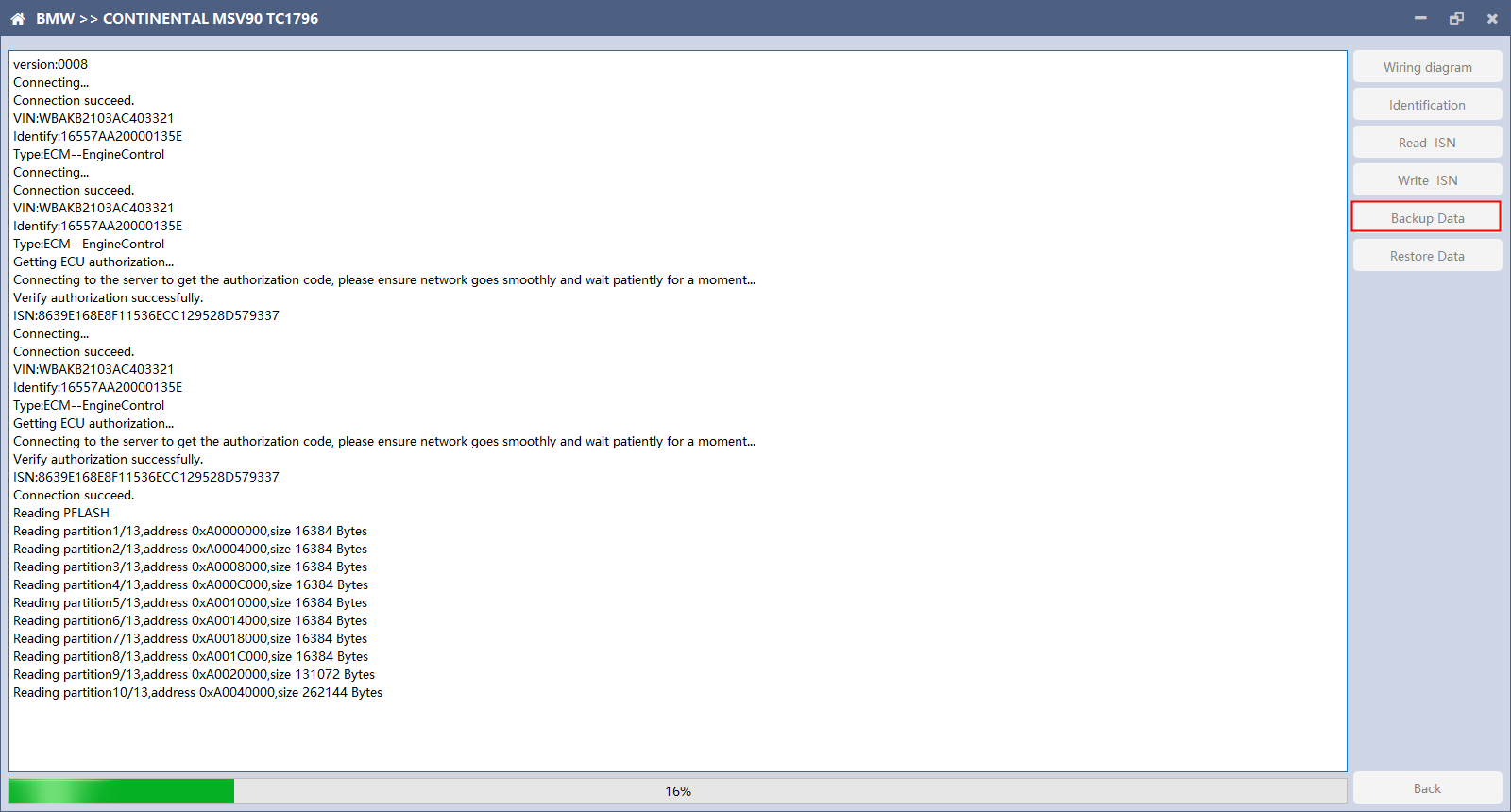

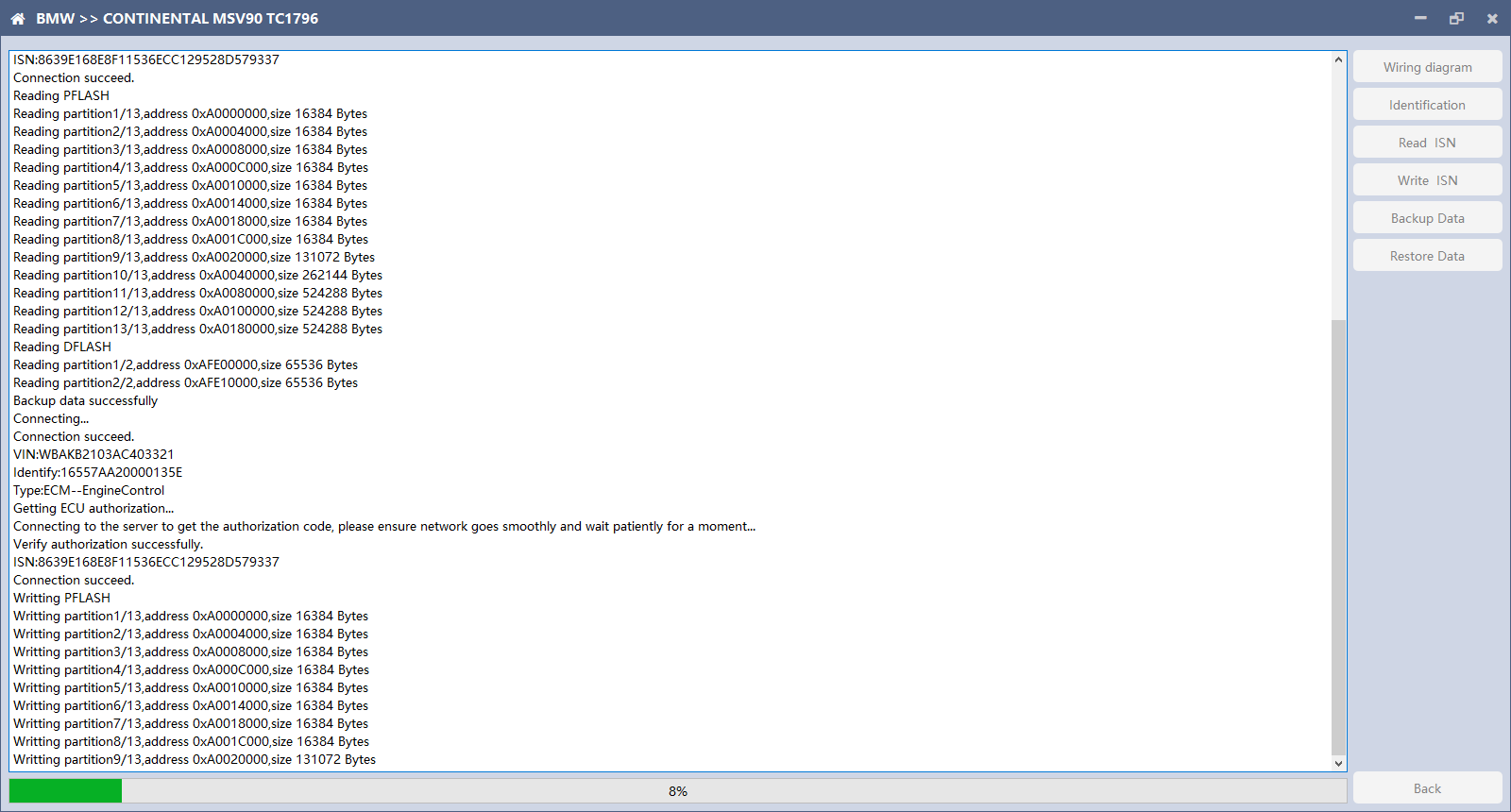

5. Backup Data

Click “Backup Data” to back up the ECU data. After reading, please save the data for subsequent use.

Note: This operation needs to be connected to the network. Please ensure that the network is normal during use.

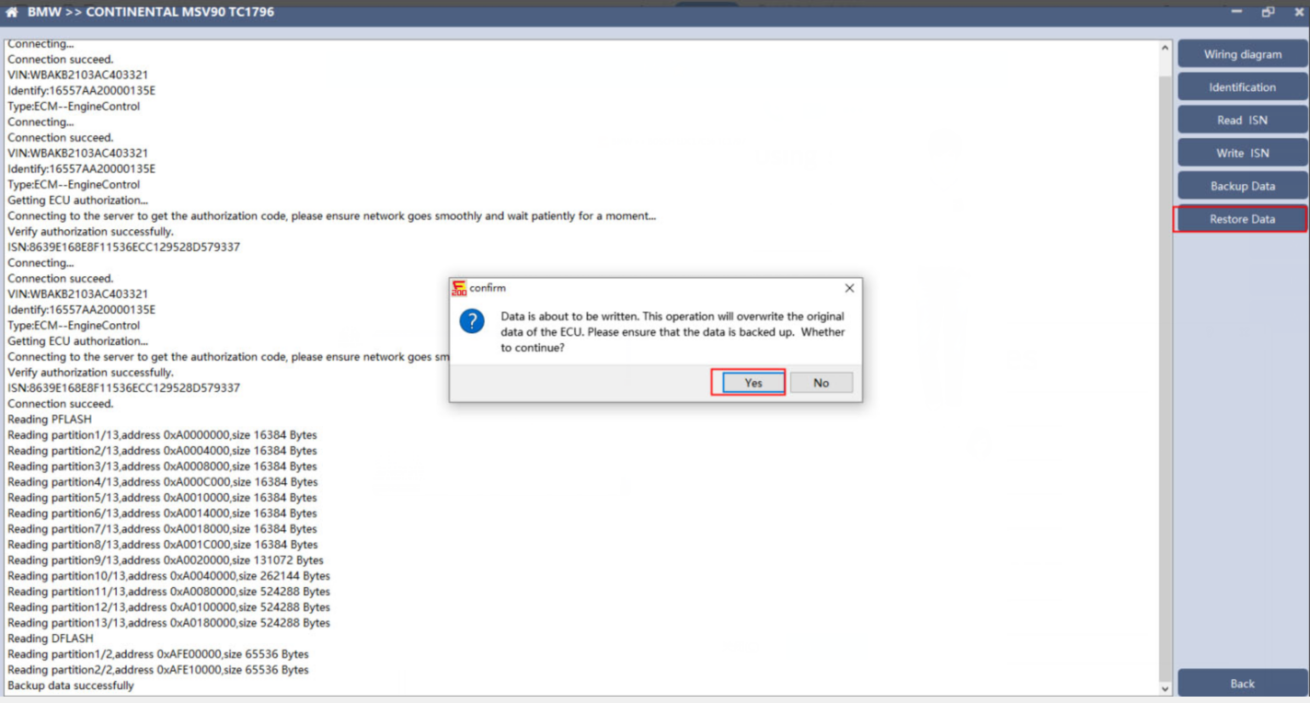

6. Data Restore

Click “Restore Data” to write the ECU data. Before writing, please make sure the data is backed up. The restored data will overwrite the current ECU data. The data can be the data of the current ECU or other ECU of the same type.

Note: During the process of data recovery, it is strictly forbidden to disconnect the device power or disconnect the device, otherwise it may cause damage to the ECU; if the software is unexpectedly shut down or the computer is shut down or crashed unexpectedly during the process of data recovery, please do not disconnect the device power or device Connect for 15 minutes, and the device can complete data recovery independently.

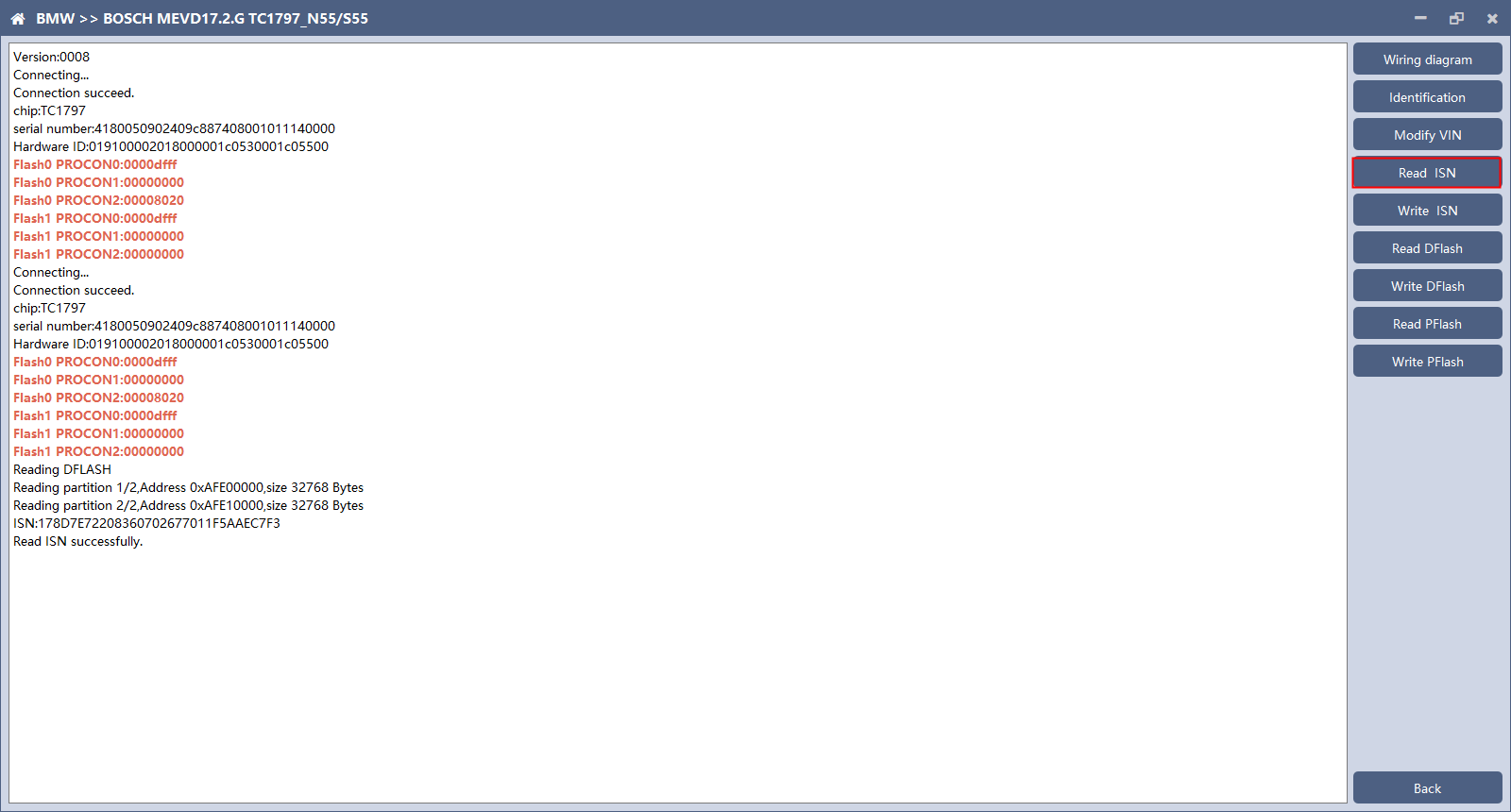

3. N13/N20/N55/B38/TC17X

The FC200 currently supports ISN read / write, VIN modification, and data read / write functions for the N13 / N20 / N55 / B38 / TC17X F series chassis of BMW models.

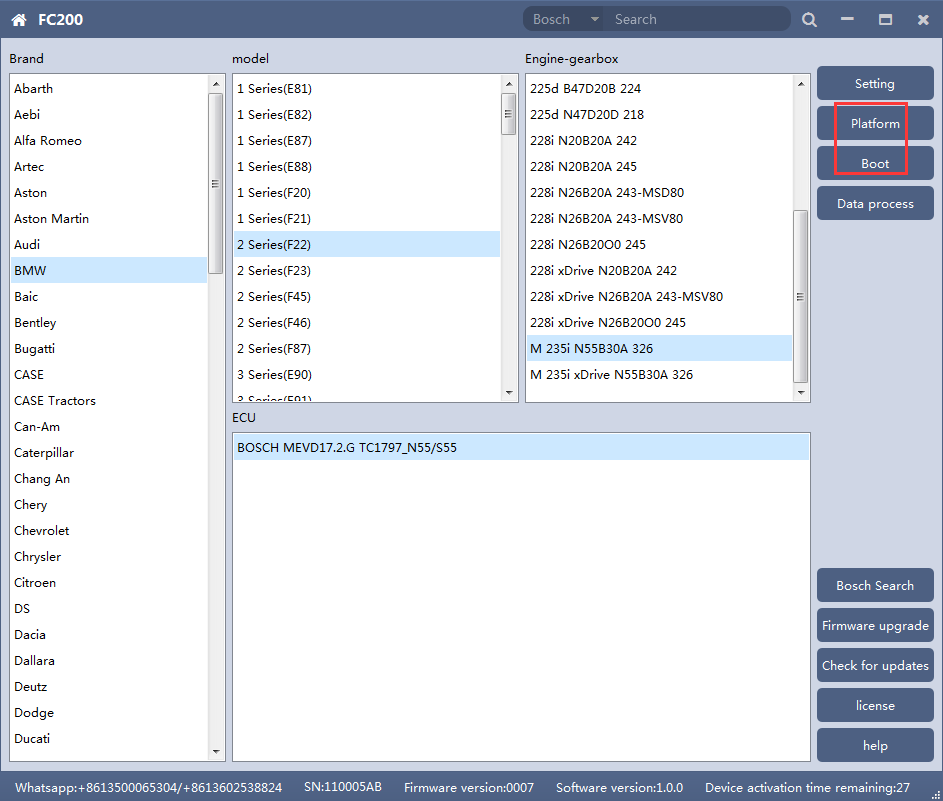

1. Determine the type of ECU according to the vehicle model, and select the correct model, otherwise it will not operate normally.The following is described with N55.

After selecting the correct ECU model, the “Platform” button will appear on the right. As shown in the figure above, click the “Platform” button to enter the ECU operation interface.

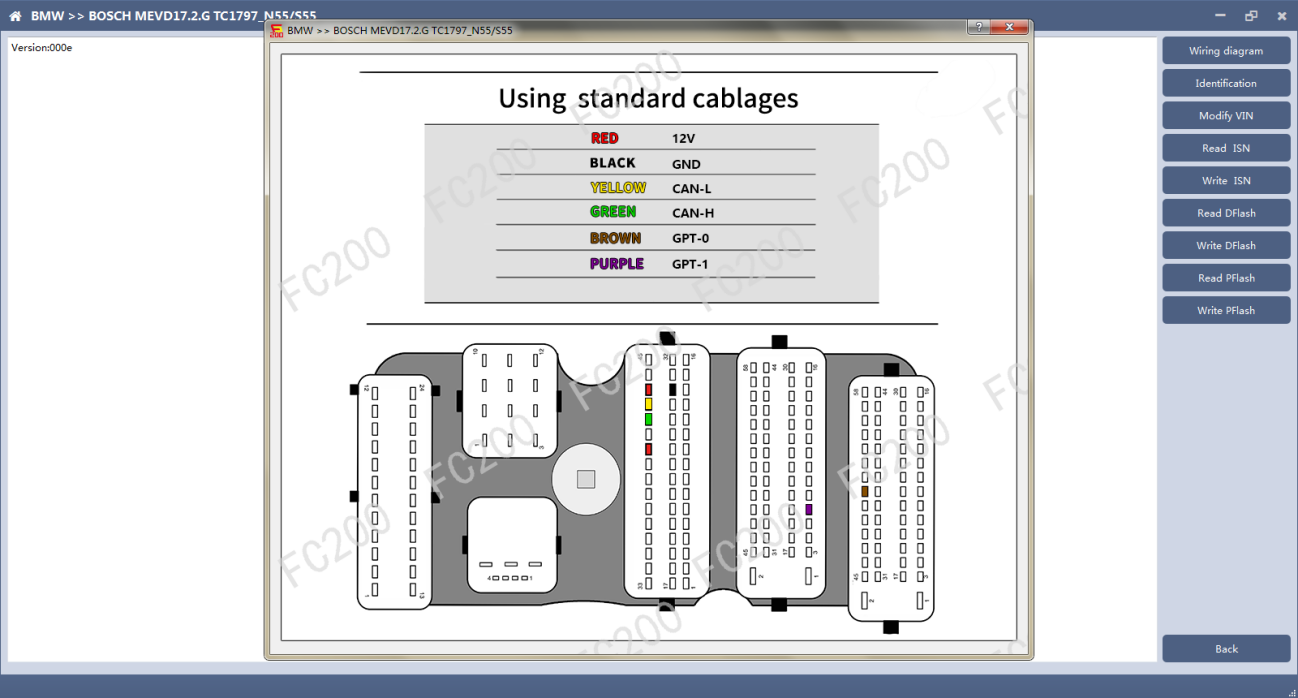

2. View wiring diagram

Click the “Wiring Diagram” button to view the ECU wiring diagram, connect the wiring harness correctly according to the wiring diagram, and connect with the device, plug in the device DC12V interface with 12V power supply.

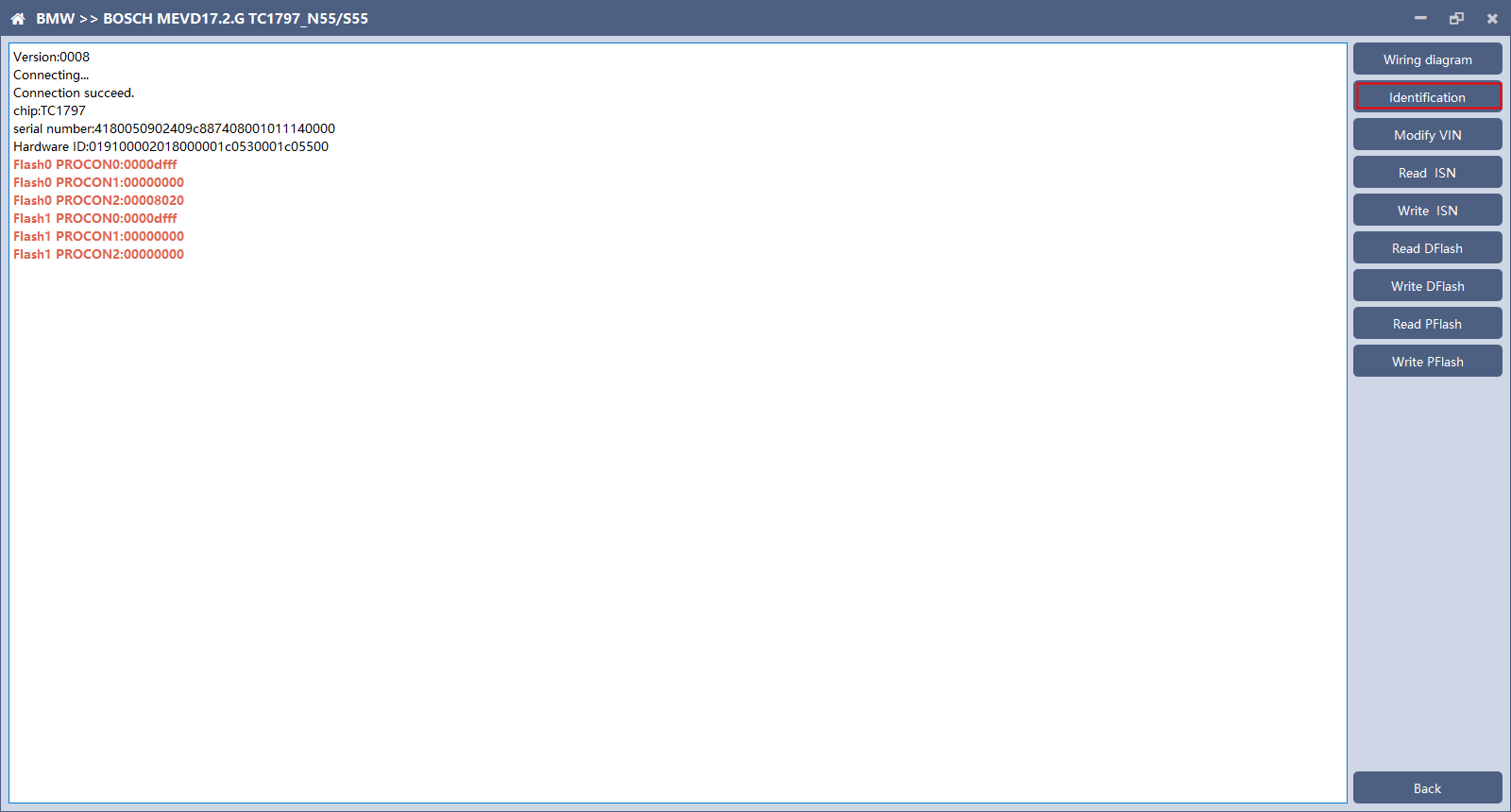

3. Identifying the ECU

Click the “Identification” button to read the ECU related information, as shown in the figure above.

4. Reading ISN

Click the “Read ISN” button to start reading the ISN. Wait for a while to complete the reading of the ISN.

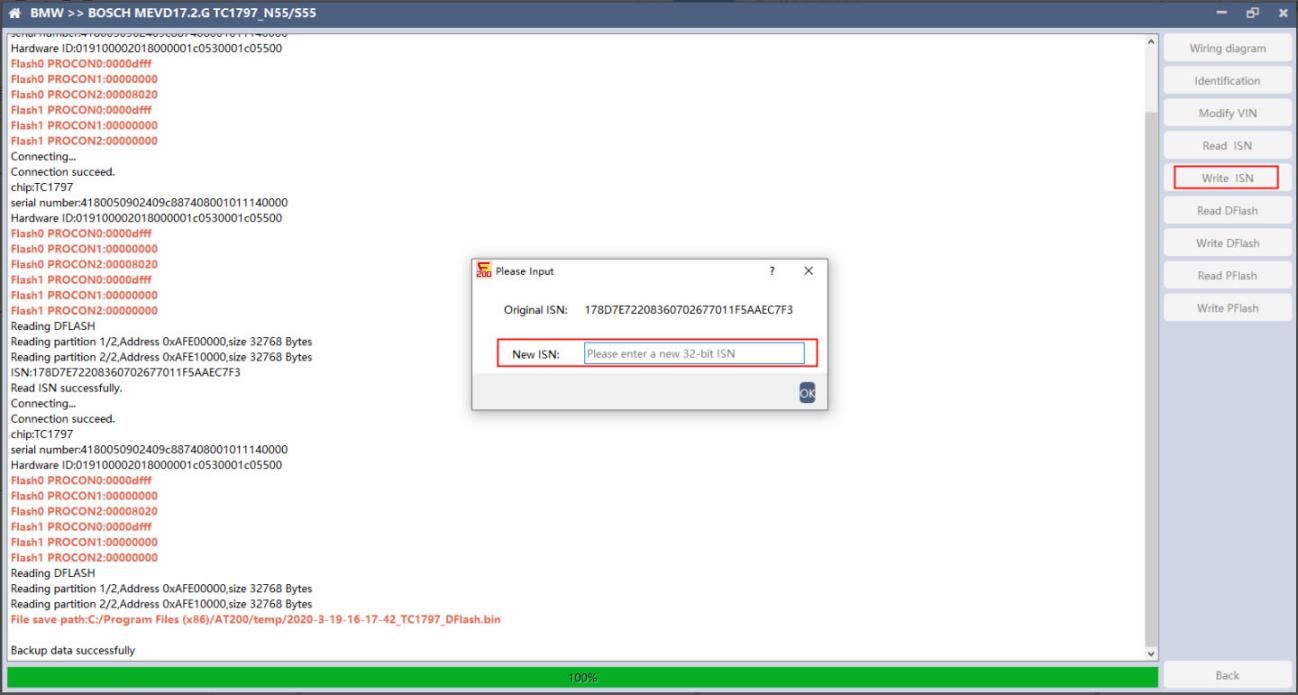

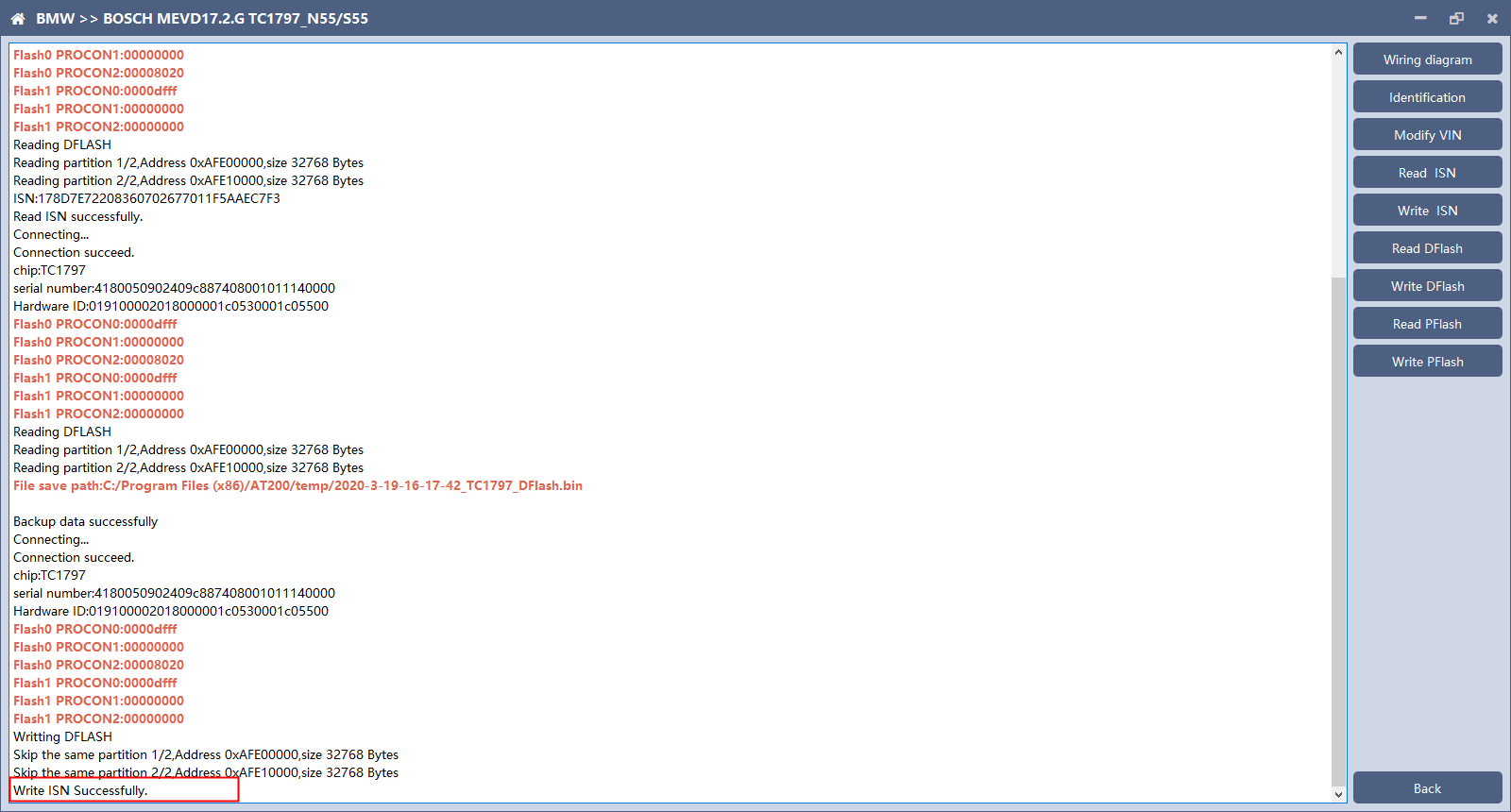

5. Writing ISN

Enter the new ISN in the edit box, and click the “OK” button to start writing the ISN.

Writing successfully。

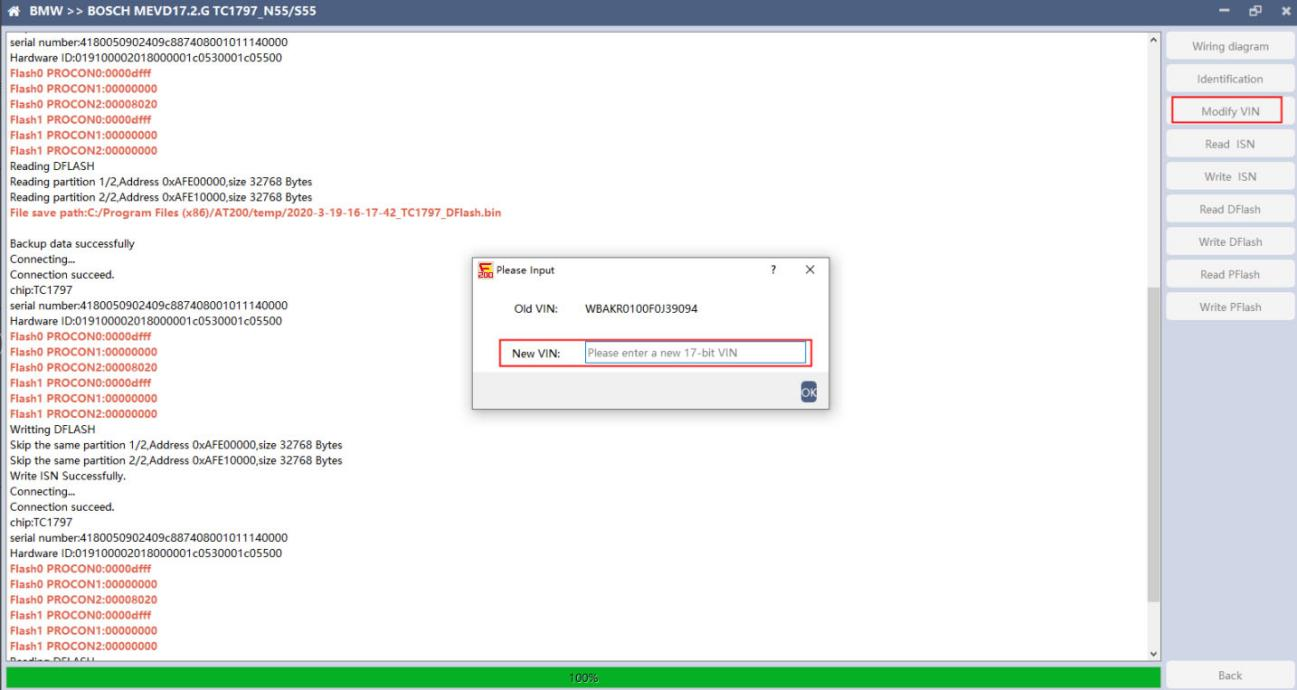

6. Modifying VIN

Enter the new VIN in the edit box, click the “OK” button to start writing VIN

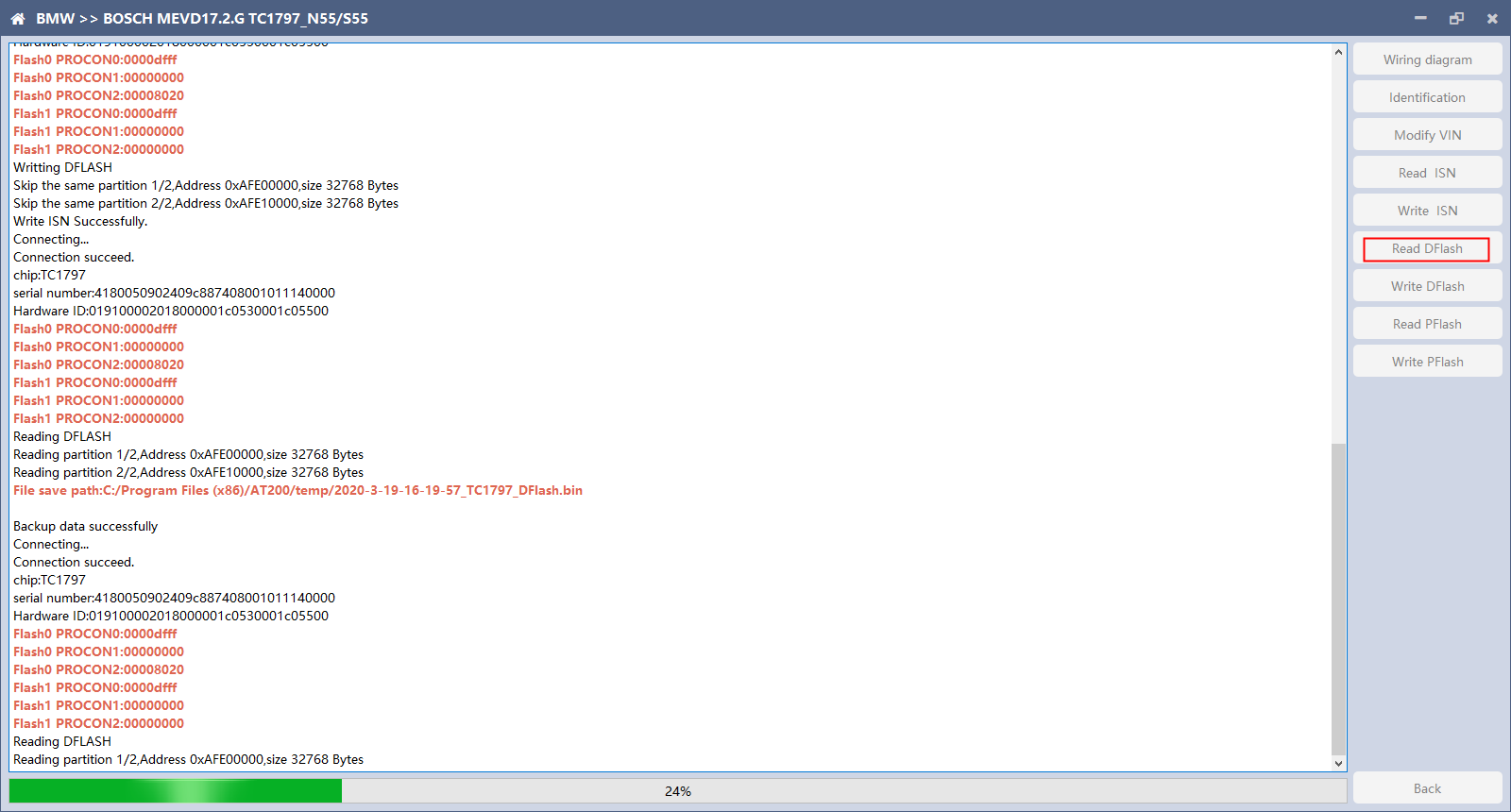

7. Reading DFlash. PFlash

Take reading DFlash as an example:

Click “Backup Data” to back up the ECU data. After reading, please save the data for subsequent use.

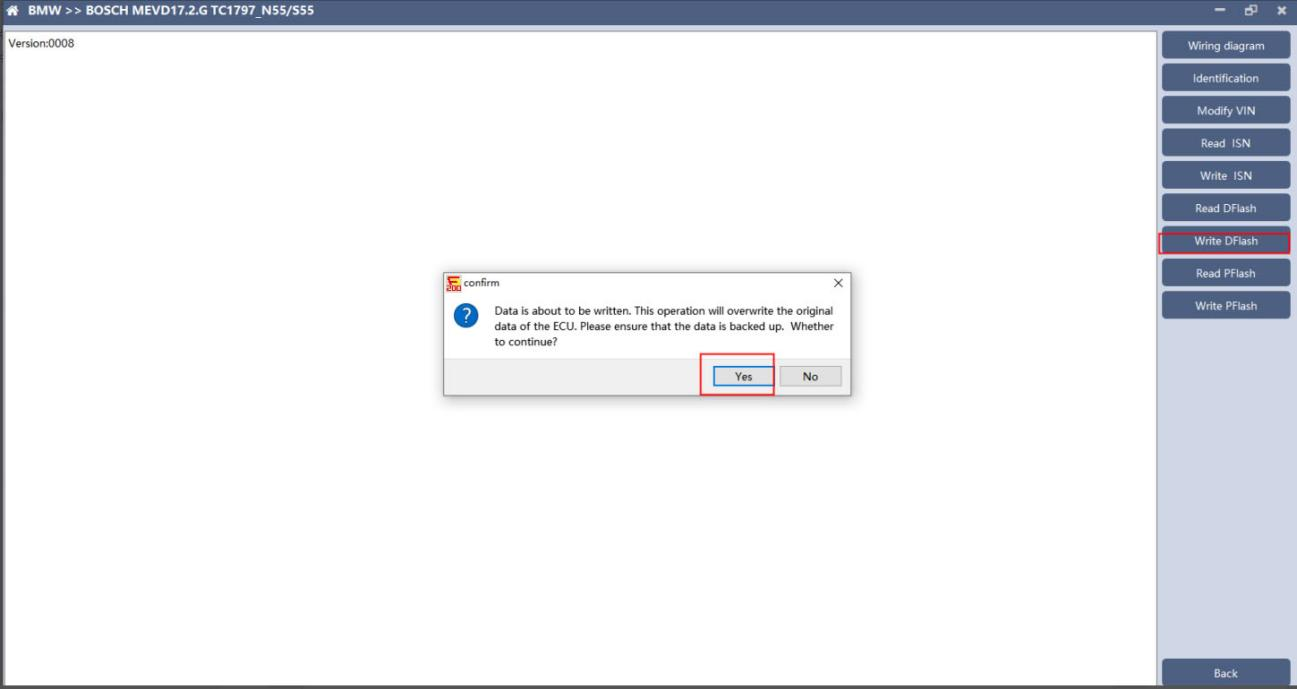

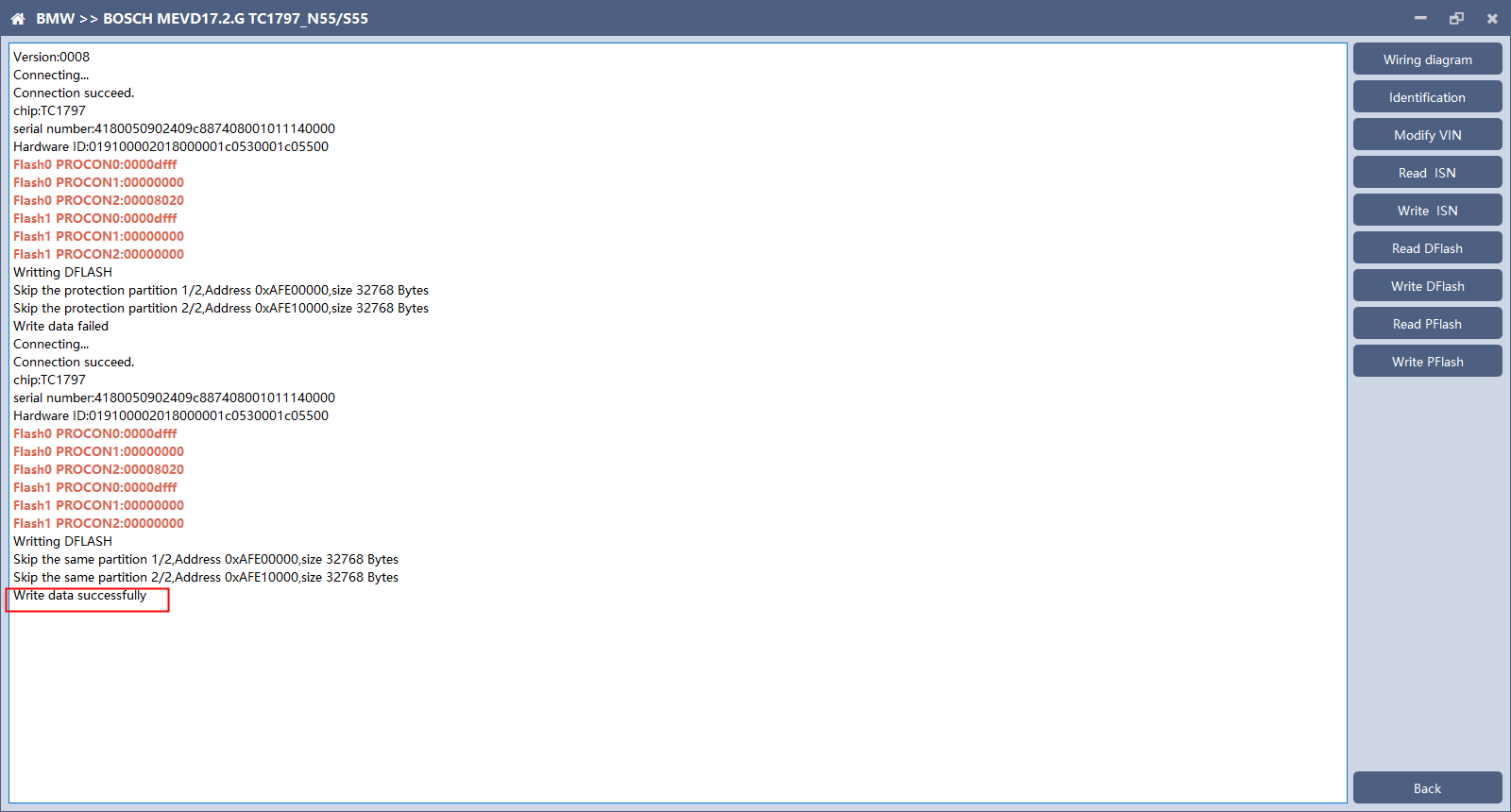

8. Writing DFlash. PFlash

Take writing DFlash as an example

Click “write DFlash” to write the ECU data. Please make sure the data is backed up before writing. The restored data will overwrite the current ECU data. The data can be the data of the current ECU or other ECU of the same type.

Note: During the data recovery process, it is strictly forbidden to disconnect the power supply or disconnect the device, otherwise it may cause ECU damage; if the software is shut down unexpectedly or the computer is shut down or crashed unexpectedly during the data recovery process, please do not disconnect the power supply or device Connect for 15 minutes, and the device can complete data recovery independently.

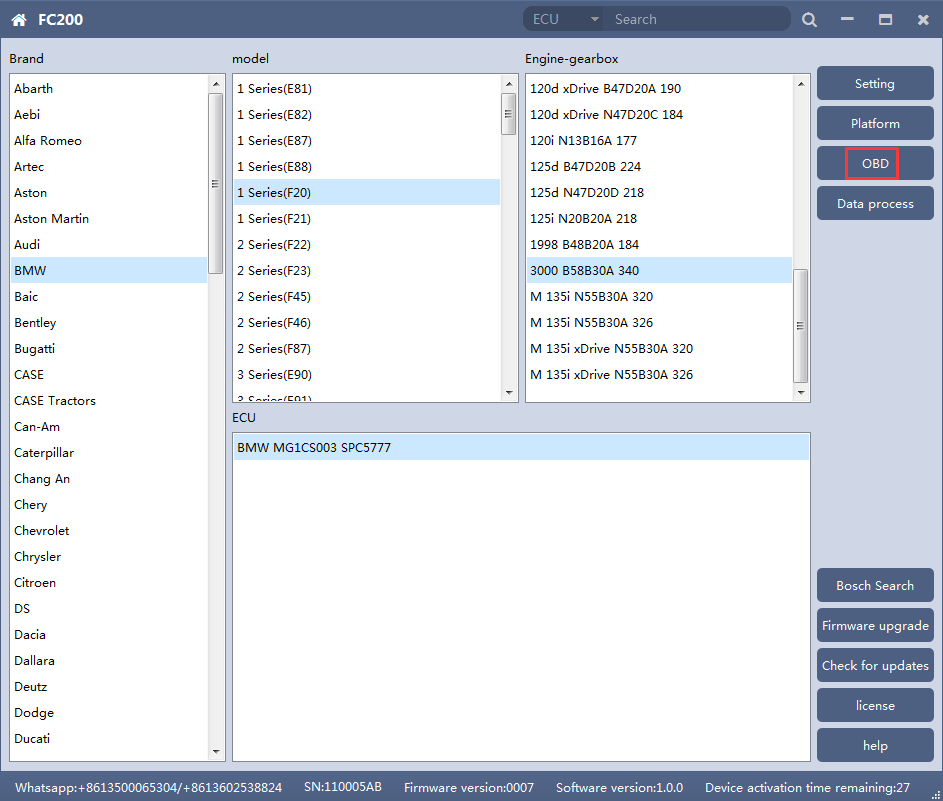

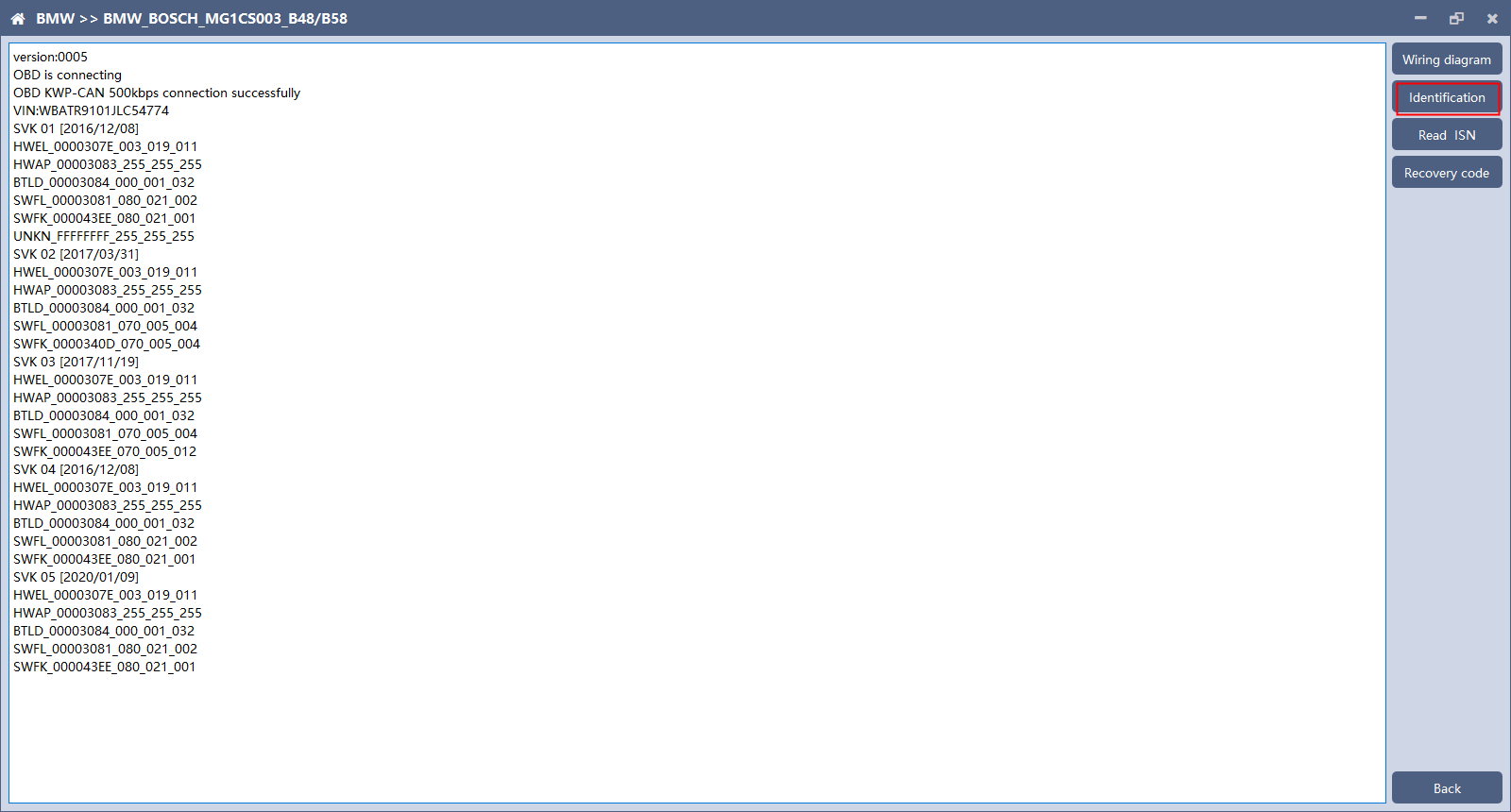

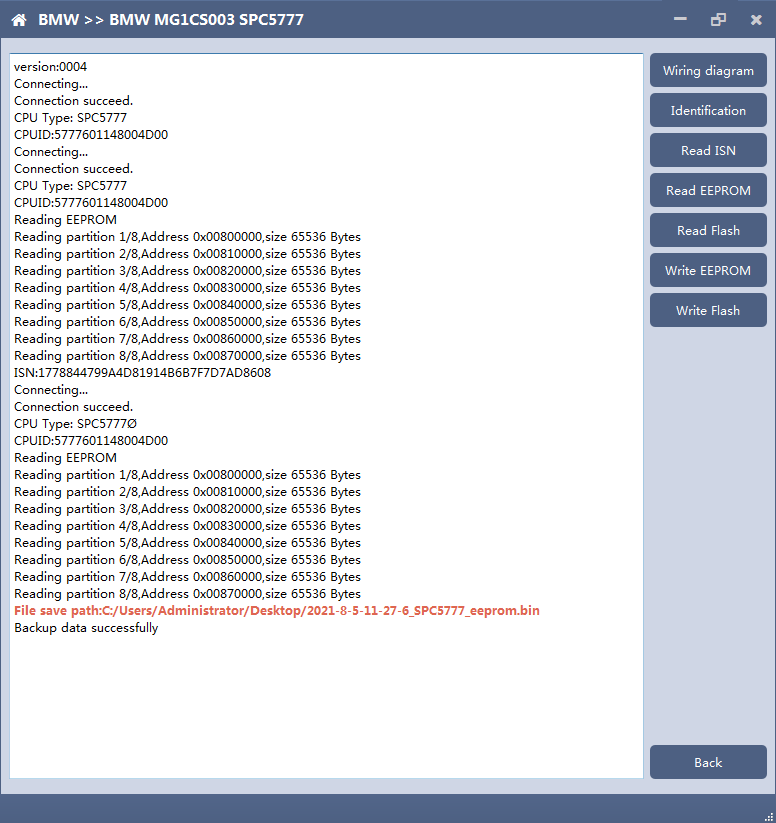

4. B48/B58

Car ECU Programmer FC200 currently supports the OBD reading ISN of BMW F020 and G series S15 models B48 and B58, and the platform SPC5777 chip and TC298 chip reading ISN and reading and writing EEPROM and FLASH.

1 OBD read ISN

1.1 Determine the type of ECU according to the model, and select the correct model, otherwise it will not operate normally.The following is described with B48.

1.2 Identifying ECU

1.3 Reading ISN

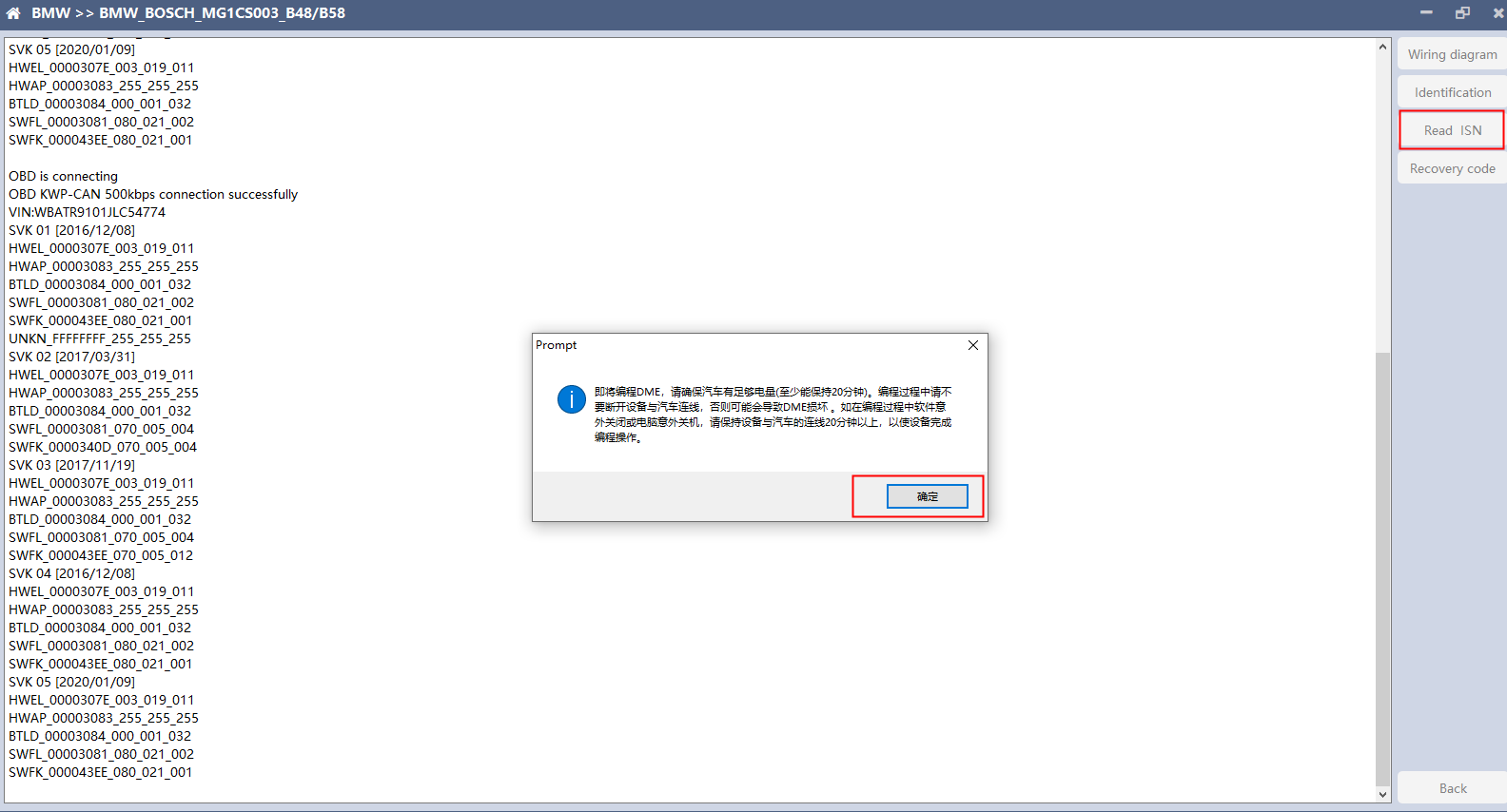

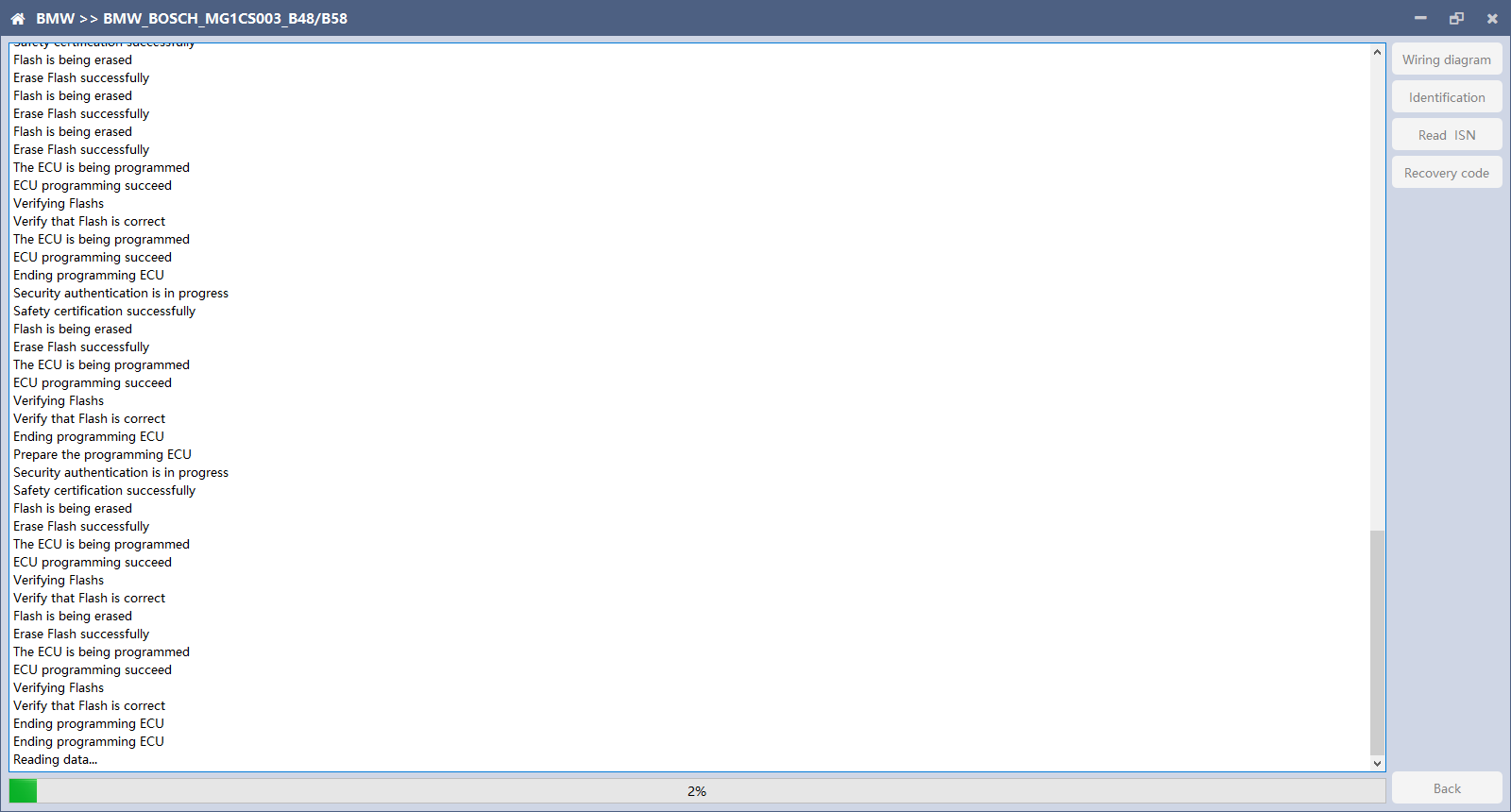

Click the “Read ISN” button to start reading the ISN. If it is the first reading, you need to program the ECU before reading. The programming time will take about 25 minutes, please be patient.

Note: During the programming process, it is strictly forbidden to disconnect the power supply of the device or disconnect the device wiring, otherwise it may cause damage to the ECU; if the software is closed unexpectedly or the computer is shut down or crashed unexpectedly during data restore, please do not disconnect the device power or device connection On-line, hold for more than 25 minutes, the device can complete programming independently.

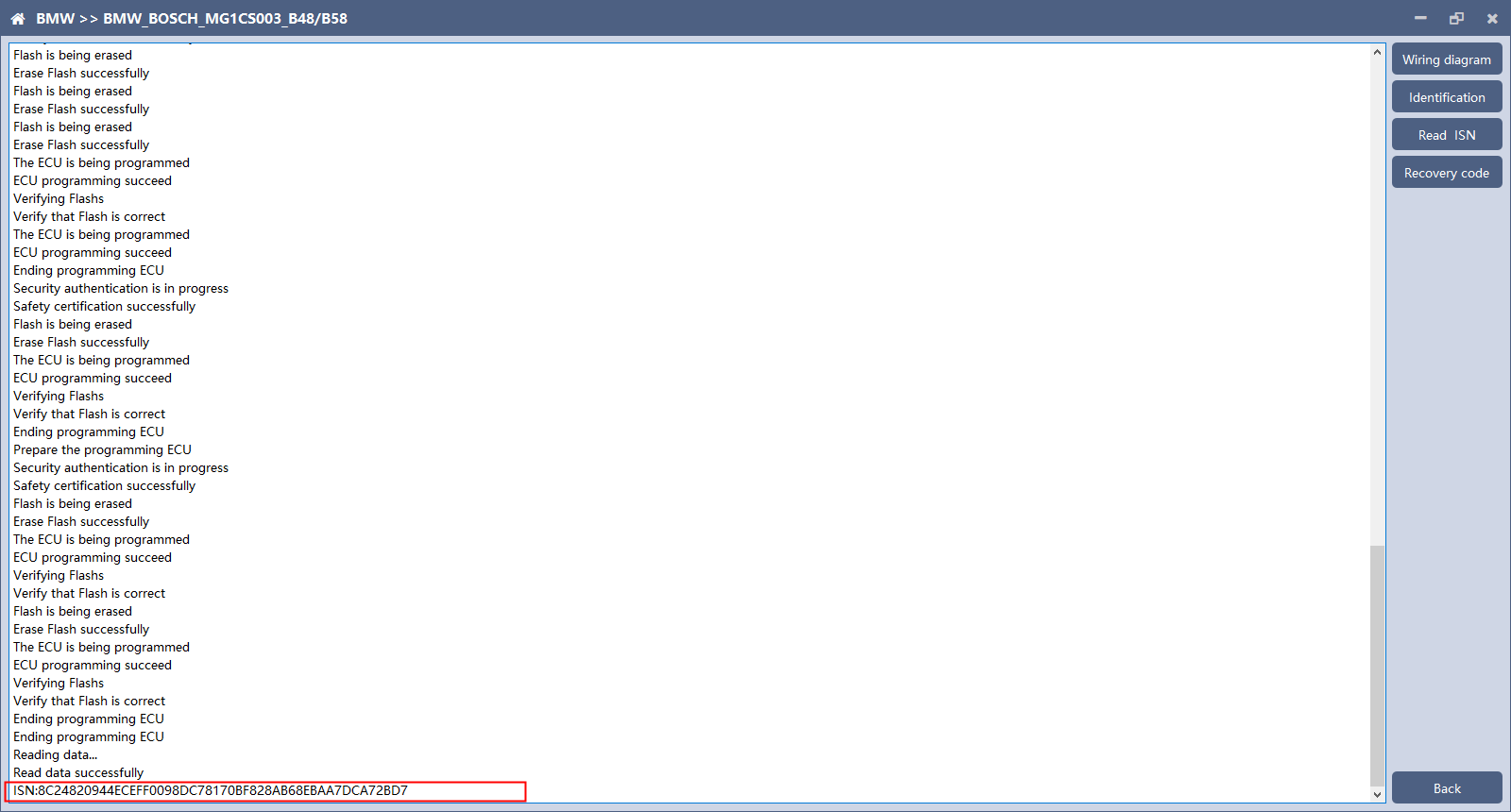

After the programming is completed, if there is a coding file before the ECU programming, the coding recovery will be performed automatically. After programming, the software starts to read data, as shown in the figure above.

Finish reading the ISN.

2. Read ISN on bench

2.1 Determine the type of ECU according to the model, and select the correct model, otherwise it will not operate normally.The wrong choice of the two types of chips will have no effect.

After selecting the correct ECU model, the “Platform” button will appear on the right. As shown in the figure above, click the “Platform” button to enter the ECU operation interface.

2.2 View wiring diagram

Click the “Wiring Diagram” button to view the ECU wiring diagram, connect the wiring harness correctly according to the wiring diagram, and connect with the device, plug in the device DC12V interface with 12V power supply.

2.3 Identifying the ECU

How-to-use-CG-FC-200-ECU-Programmer-34

2.4 Reading ISN

2.5 Reading EEPROM/Flash

Take reading EEPROM as an example

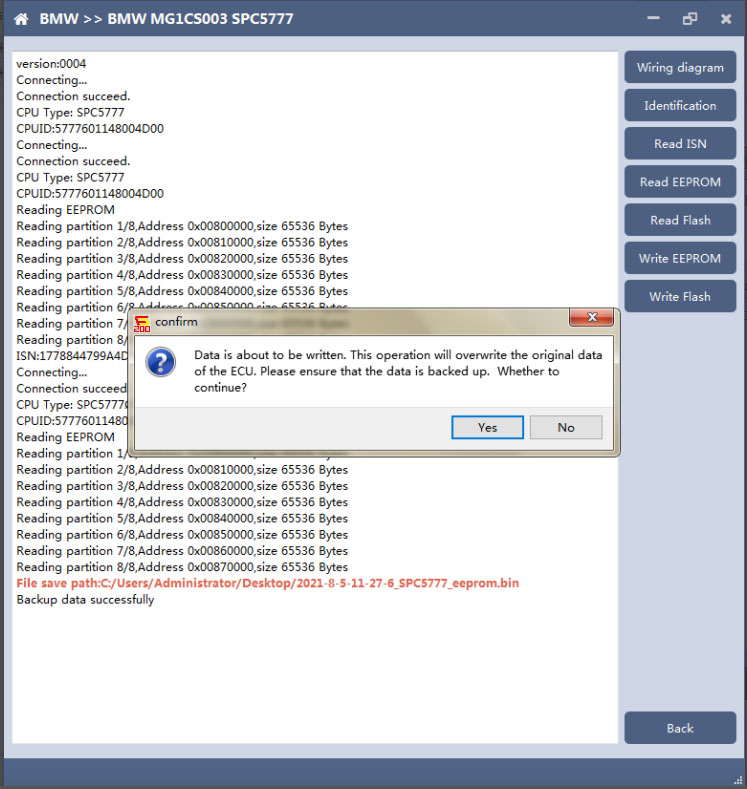

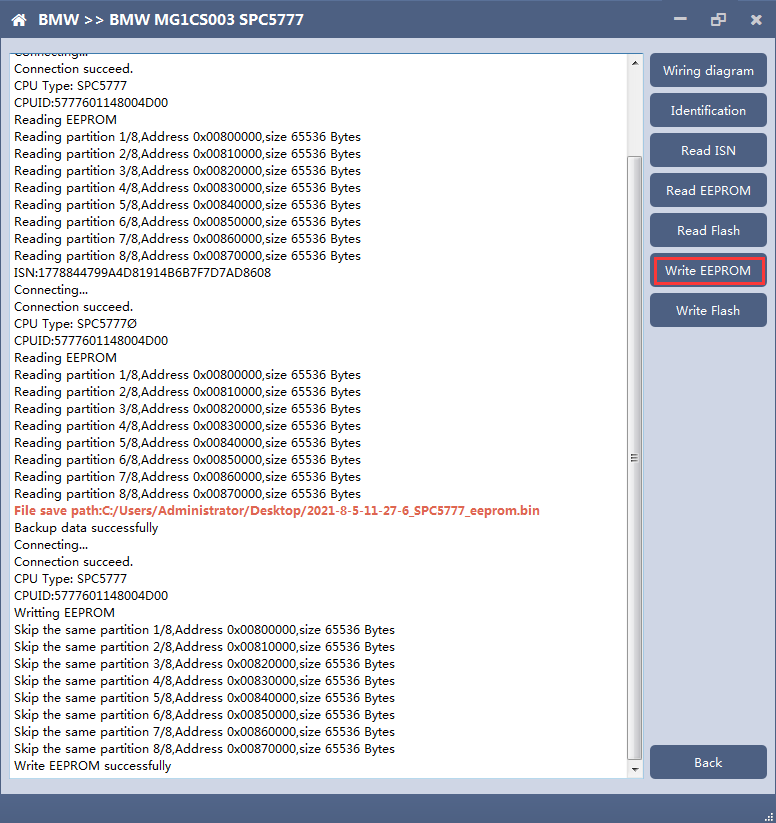

2.6 Writing EEPROM/Flash

Take reading EEPROM as an example.Make sure to save a copy of the original data before writing data

Note: During the data recovery process, it is strictly forbidden to disconnect the power supply or disconnect the device, otherwise it may cause ECU damage; if the software is shut down unexpectedly or the computer is shut down or crashed unexpectedly during the data recovery process, please do not disconnect the power supply or device Connect for 15 minutes, and the device can complete data recovery independently.

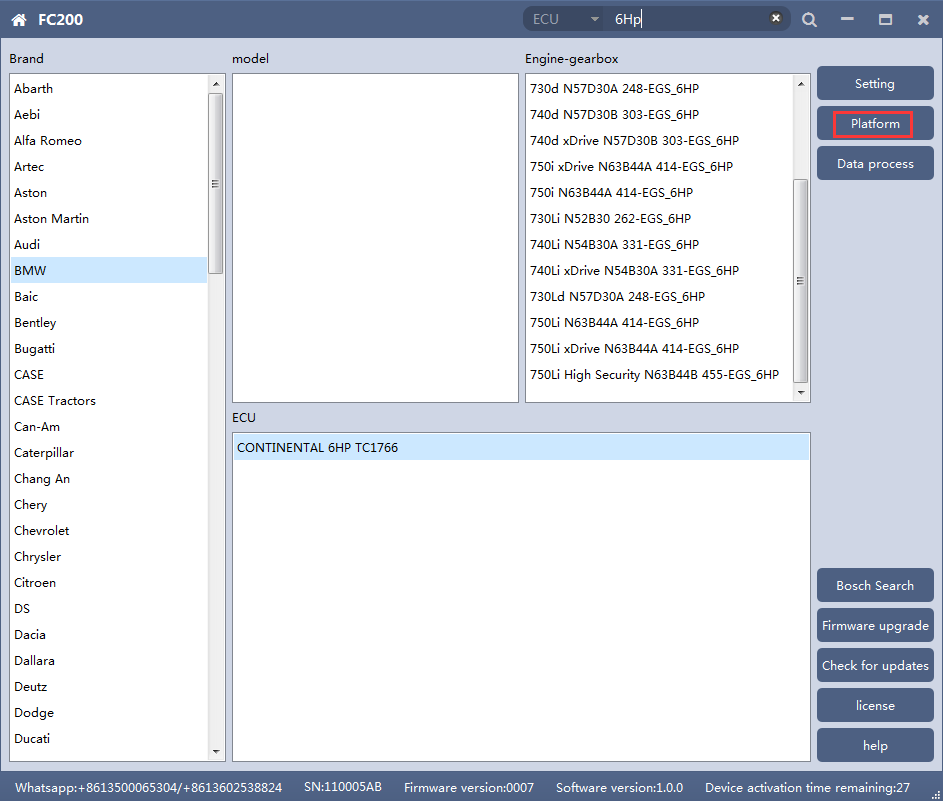

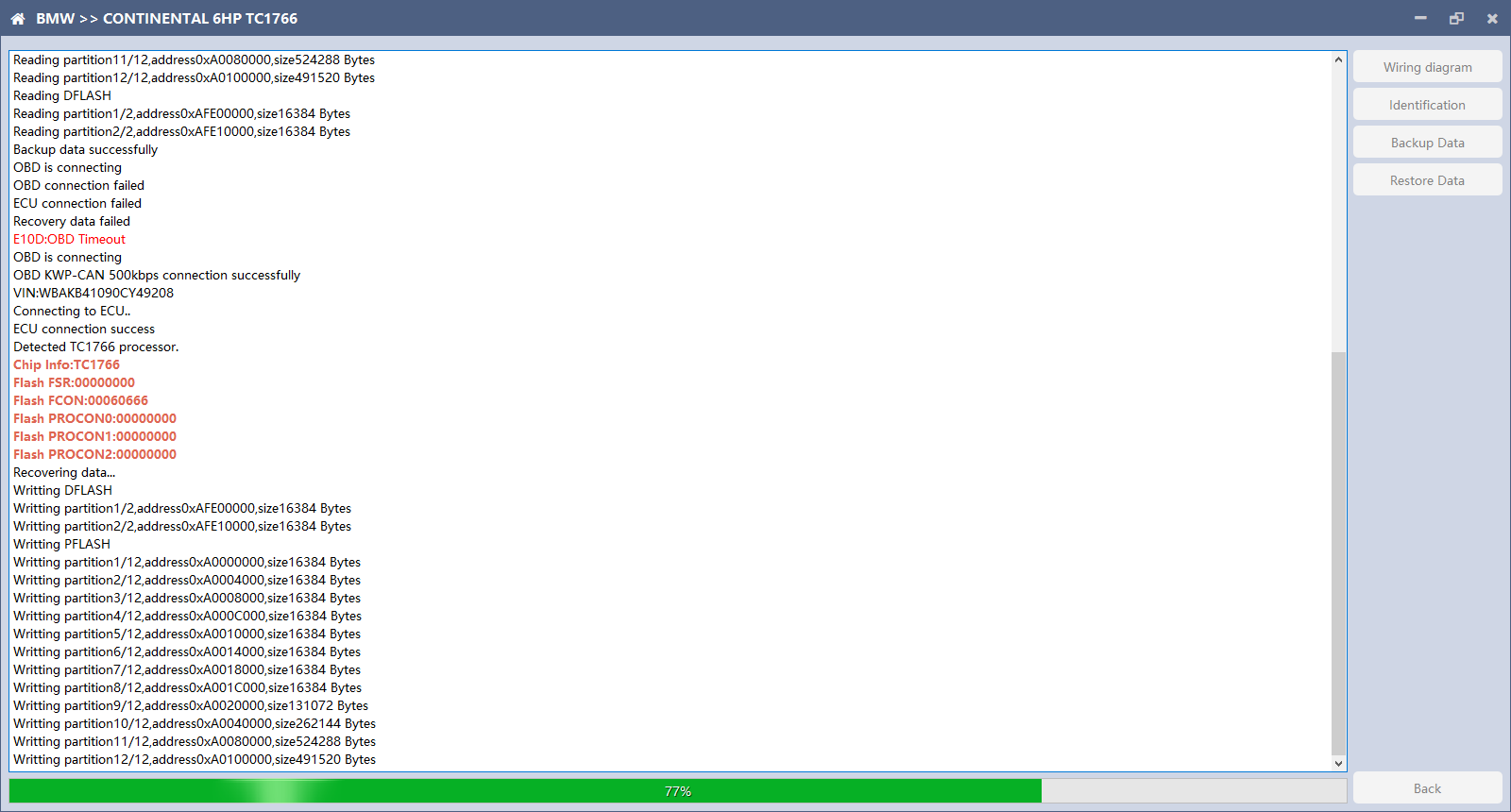

5. 6HP

The FC200 currently supports the cloning of 6HP ECUs in BMW F-series (F01, F02, F03).

1. Determine the ECU type according to the vehicle model, and select the correct model, otherwise it will not operate normally.

After selecting the correct ECU model, the “Platform” button will appear on the right. As shown in the figure above, click the “Platform” button to enter the ECU operation interface.

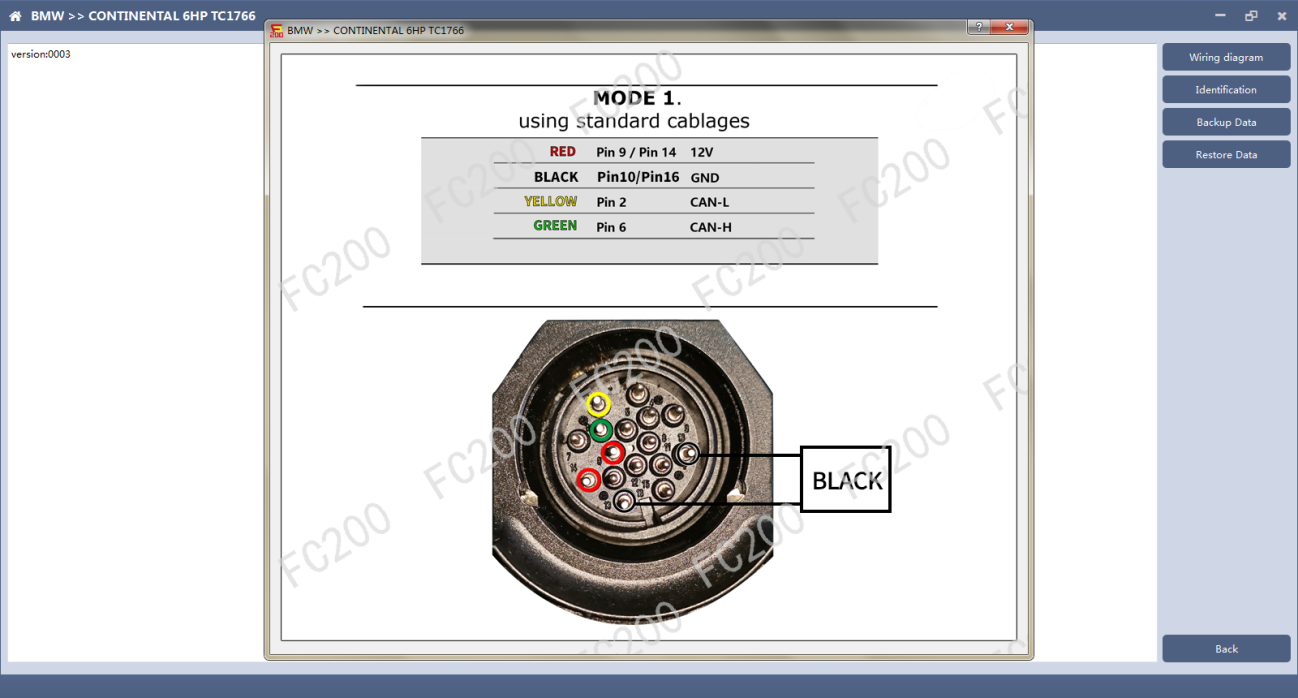

2. View wiring diagram

Click the “Wiring Diagram” button to view the ECU wiring diagram, connect the wiring harness correctly according to the wiring diagram, and connect with the device, plug in the device DC12V interface with 12V power supply.

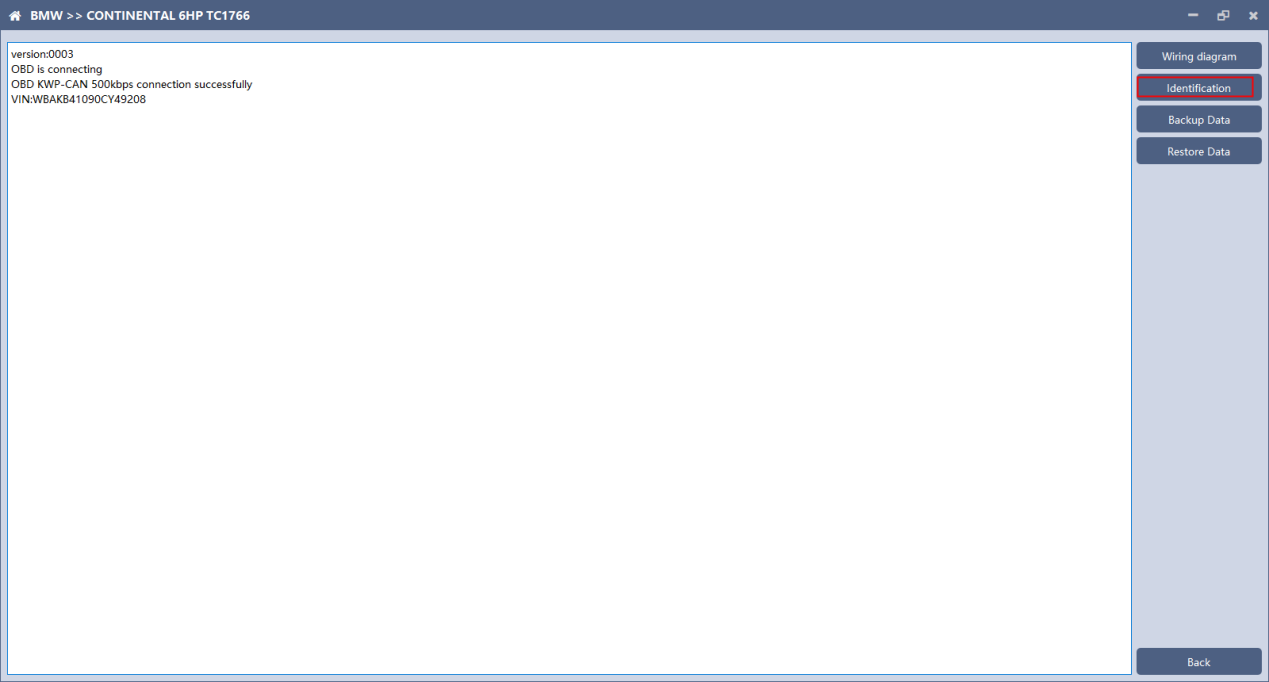

3. Identifying ECU

Click the “Identification” button to read the ECU related information, as shown above

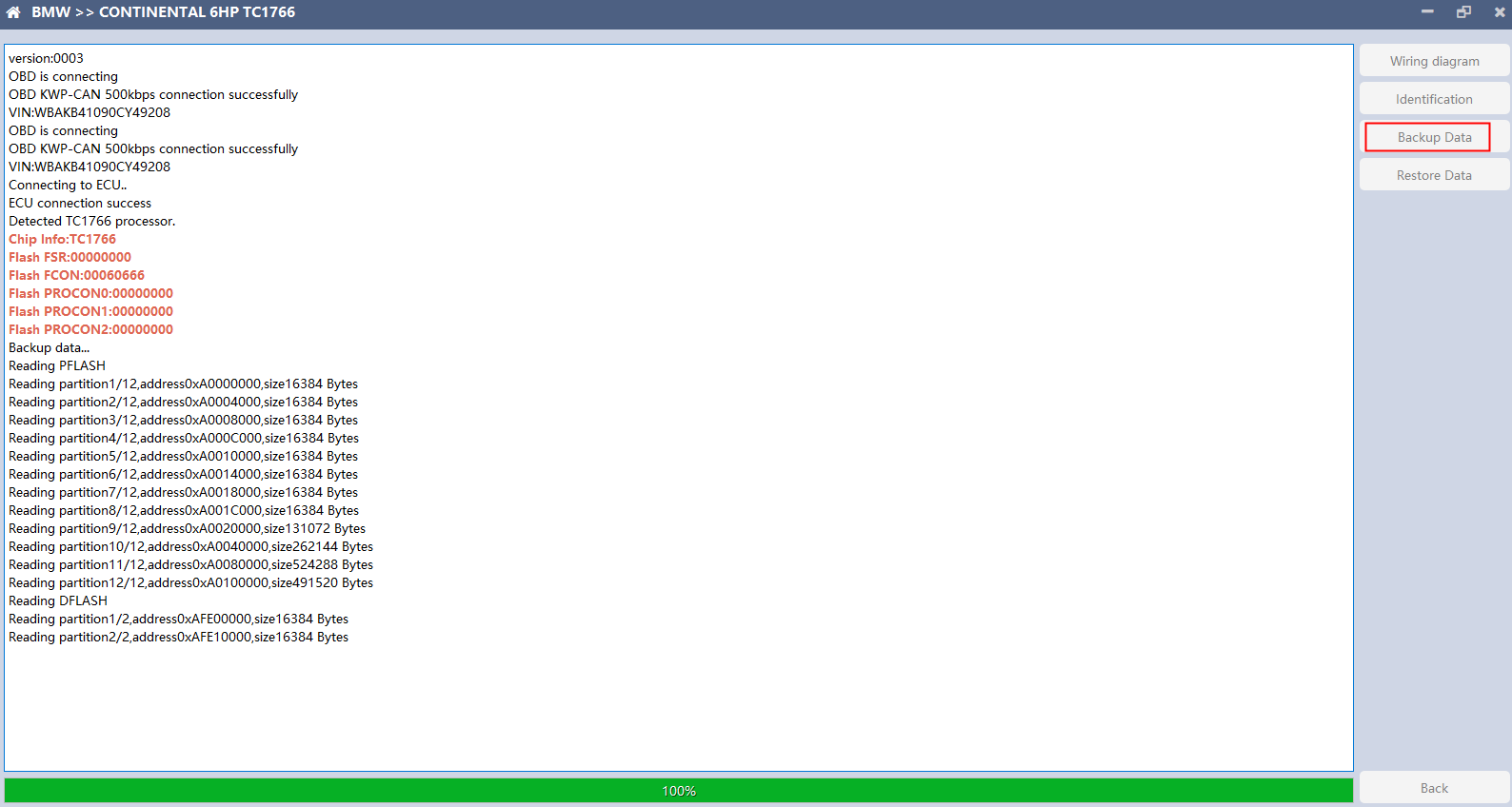

4. Backup Data

Click “Backup Data” to back up the ECU data. After reading, please save the data for subsequent use.

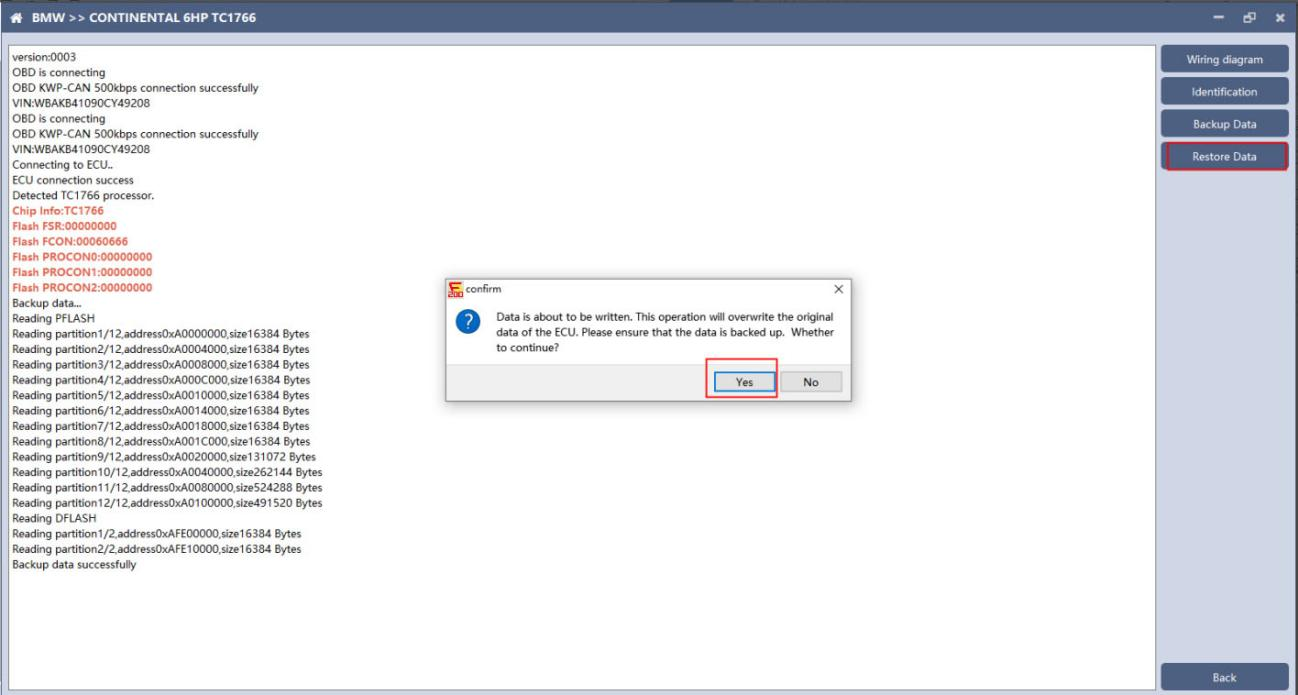

5. Data Restore

Click “Restore Data” to write the ECU data. Please make sure the data is backed up before writing. The restored data will overwrite the current ECU data. The data can be the data of the current ECU or other ECUs of the same type.

Note: During the data restore process, it is strictly forbidden to disconnect the device from the power or disconnect the device; if the software is unexpectedly shut down or the computer is shut down or crashed unexpectedly during the data recovery process, please do not disconnect the device power or the device connection for 15 minutes , The device can complete the data restore independently.

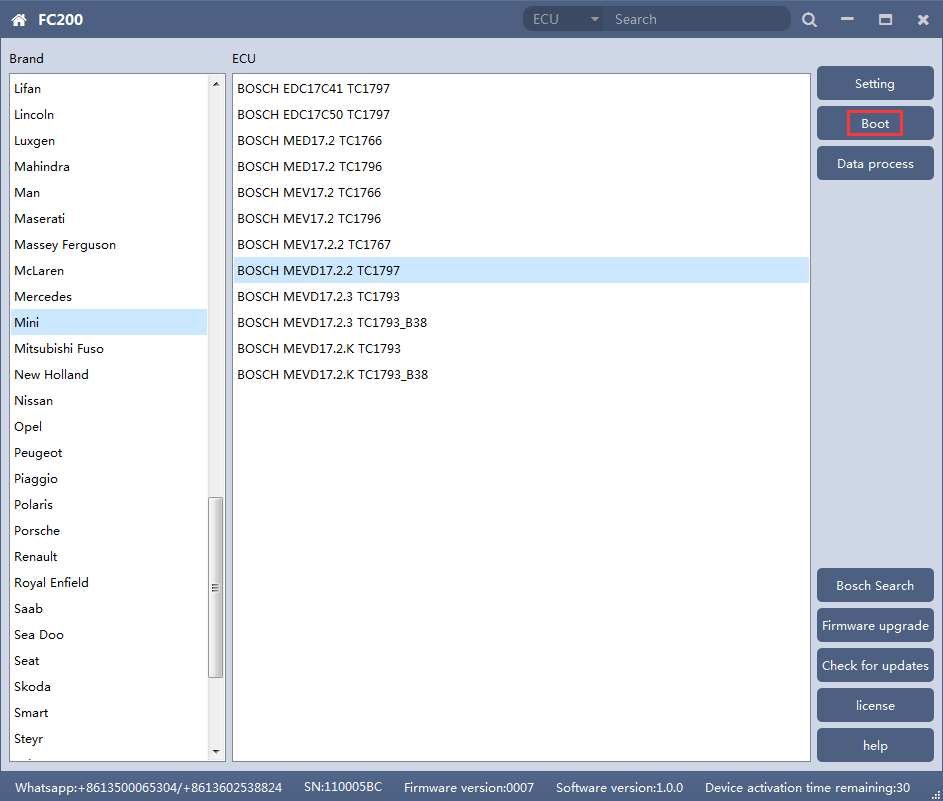

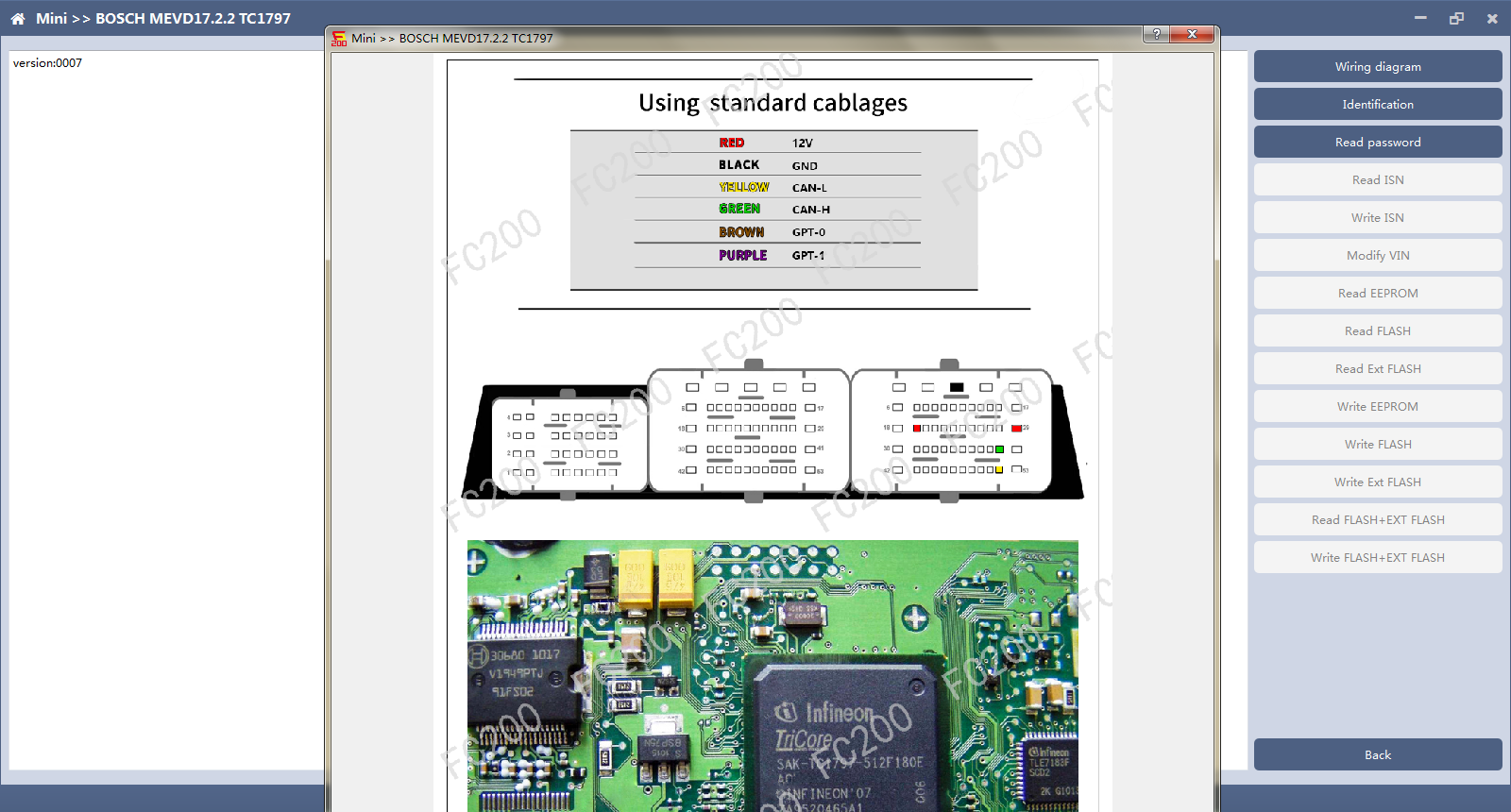

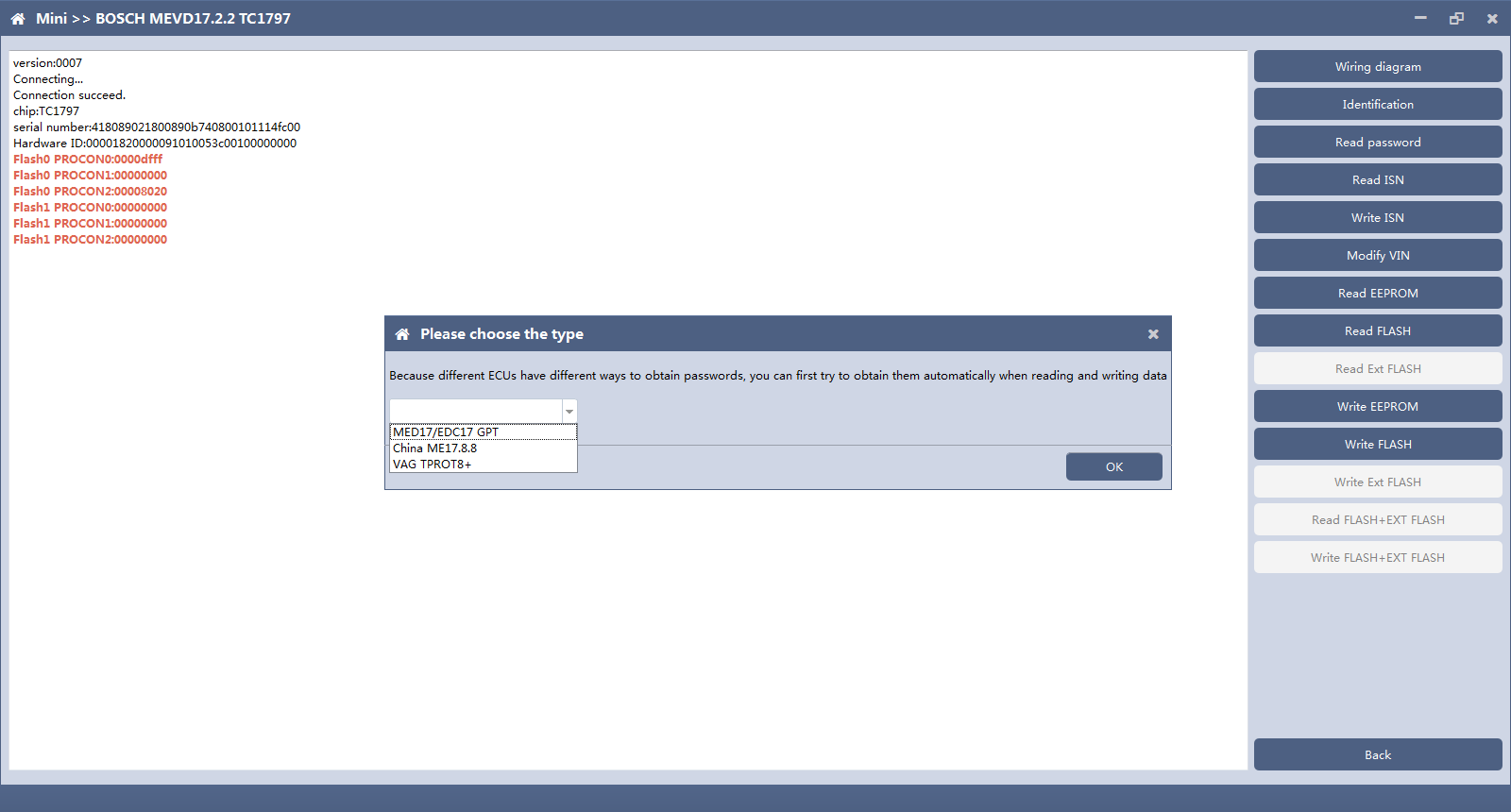

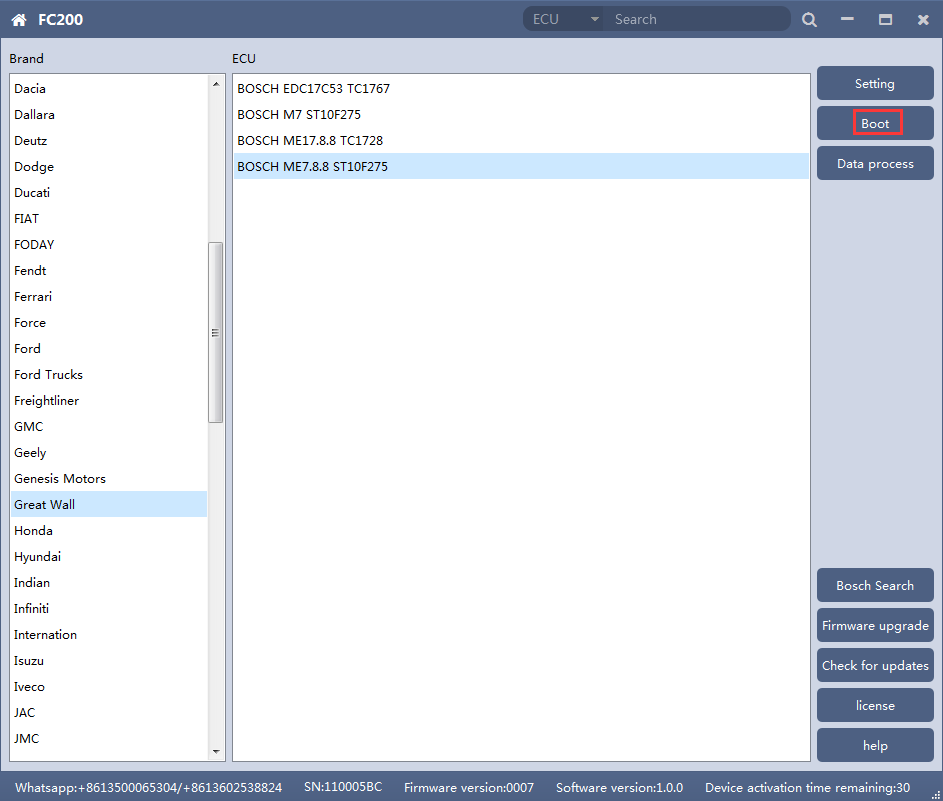

6. BOSCH BOOT(Boot)read and write data

1. The ECU type should be determined according to car type,and the model should be selected correctly, otherwise it can not operate normally.

After choosing correct ecu type, there will show a“Boot”button as shown picture above.

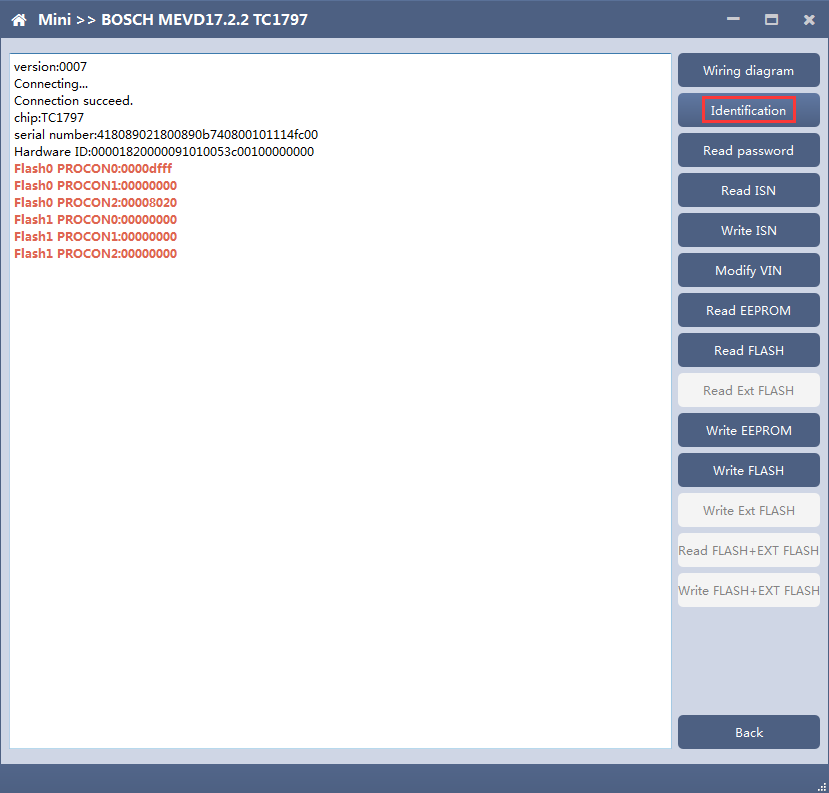

2. Check the diagram in software

3. Identify ECU

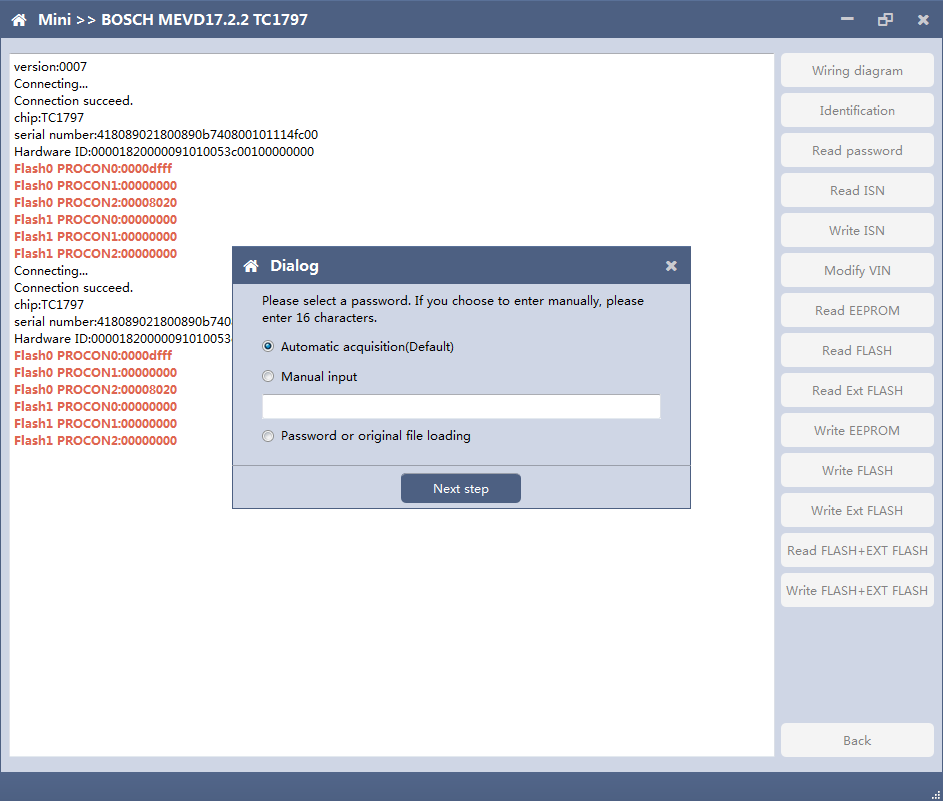

4. Read password

Pop up option box when reading password and select correct type.

5. Read/write Pflash

When reading and writing flash, please select automatic acquisition first. If it is not successful, please try other input methods.

Please note:In the process of writing data, it is strictly forbidden to disconnect the power supply or the connection of the device; if the software is shut down or the computer is shut down or crashes unexpectedly in the process of writing data, please do not disconnect the power supply or the connection of the device, and keep it for 15 minutes, the device can complete the data recovery independently.

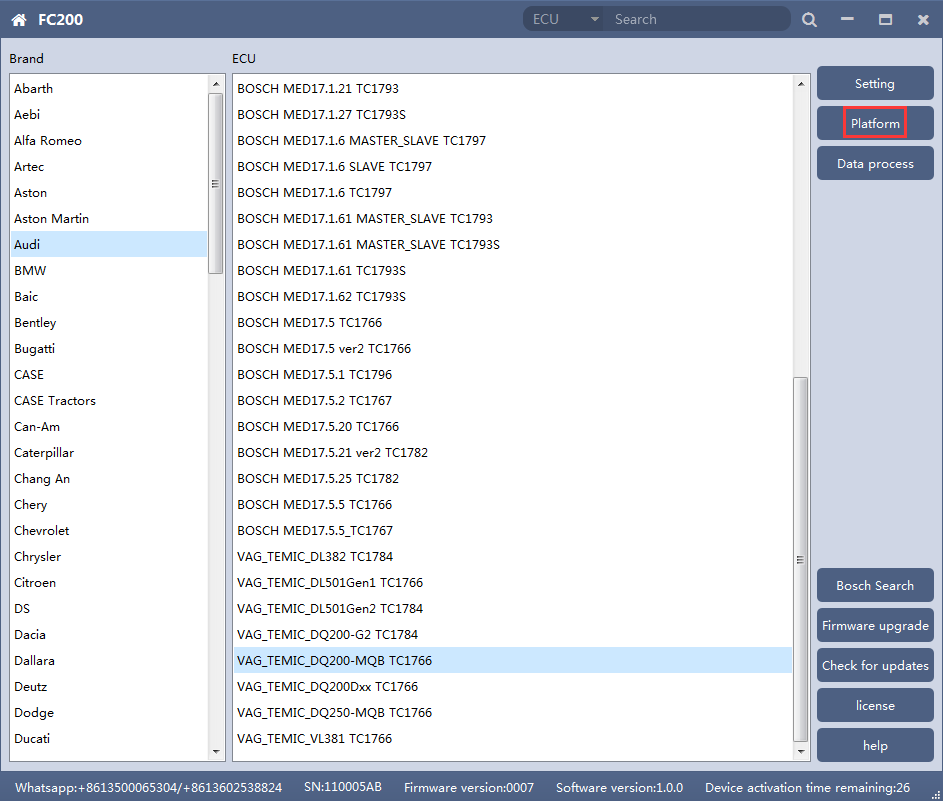

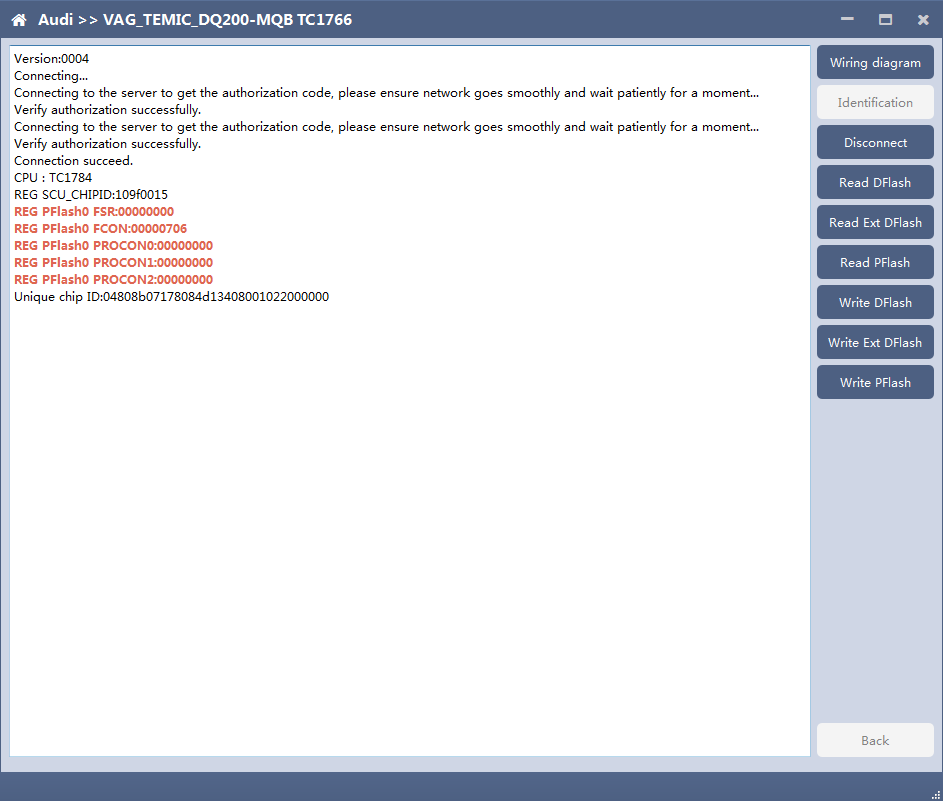

7. Volkswagen EGS read and write Flash on bench

AT-200 currently supports data reading and writing functions of DQ200 and VL381 transmissions of Audi and Volkswagen. DQ200 is taken as an example following.

1. The ECU type should be determined according to car type,and the model should be selected correctly, otherwise it can not operate normally.

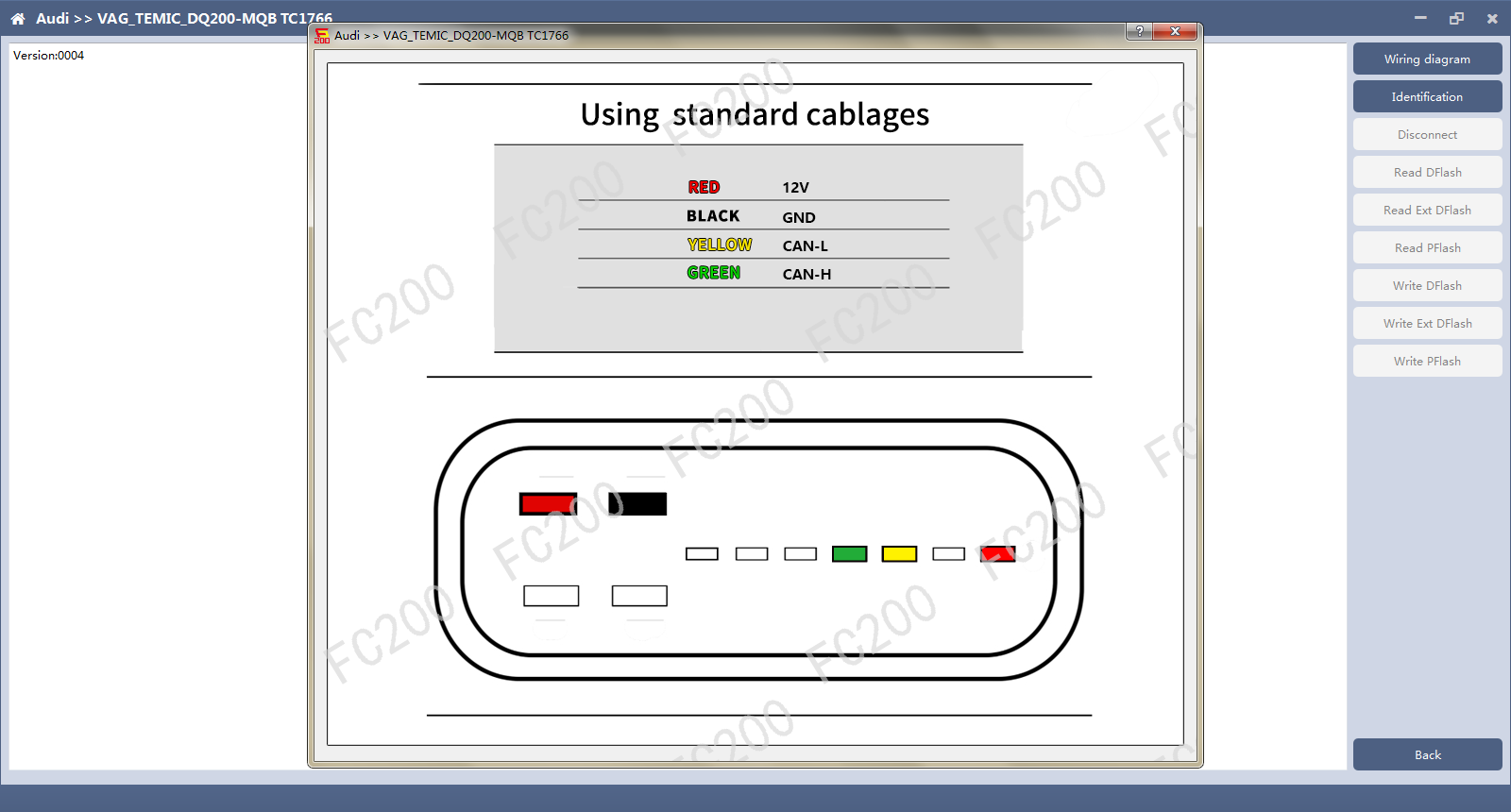

2. Check diagram

Connect cables well according software diagram

3. Identify ECU

After connecting to DQ200, the “identify” button will be grayed out. You can proceed to the next step. When you click “disconnect”, you can identify again.

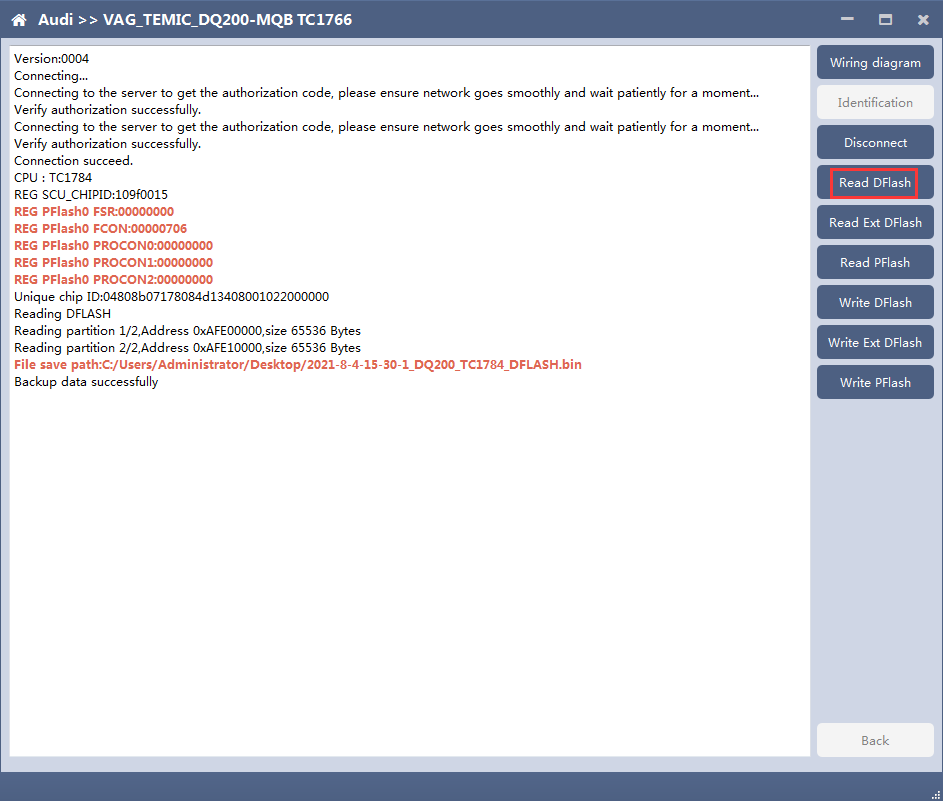

4. Read DFlash. EXT DFlash and PFlash

Take reading Dflash as an example:

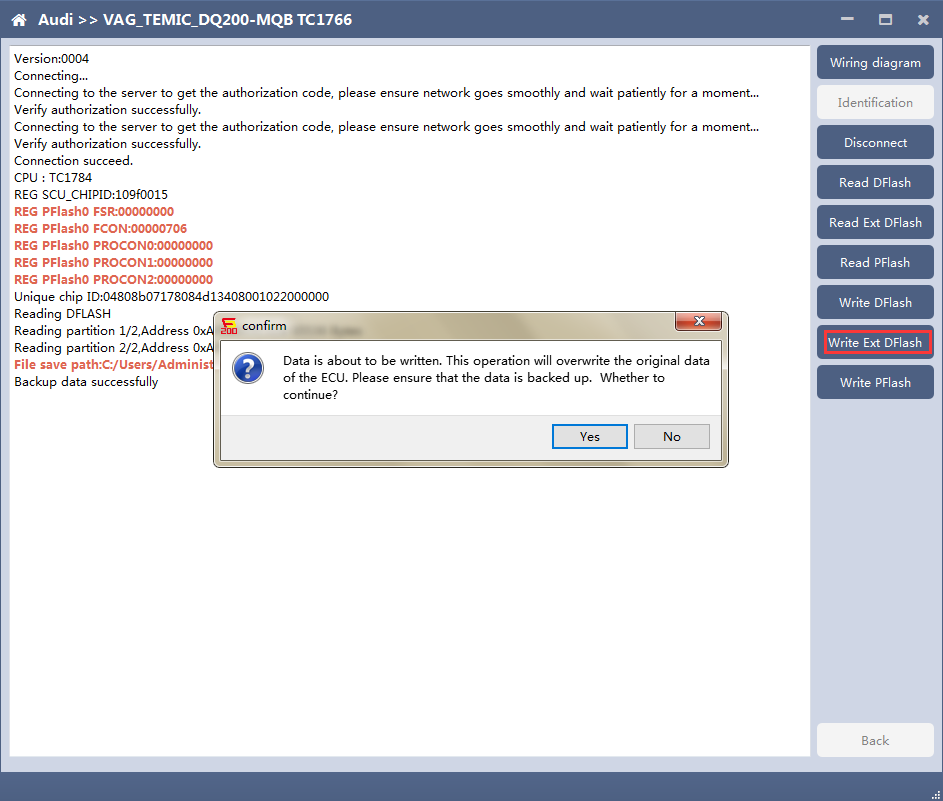

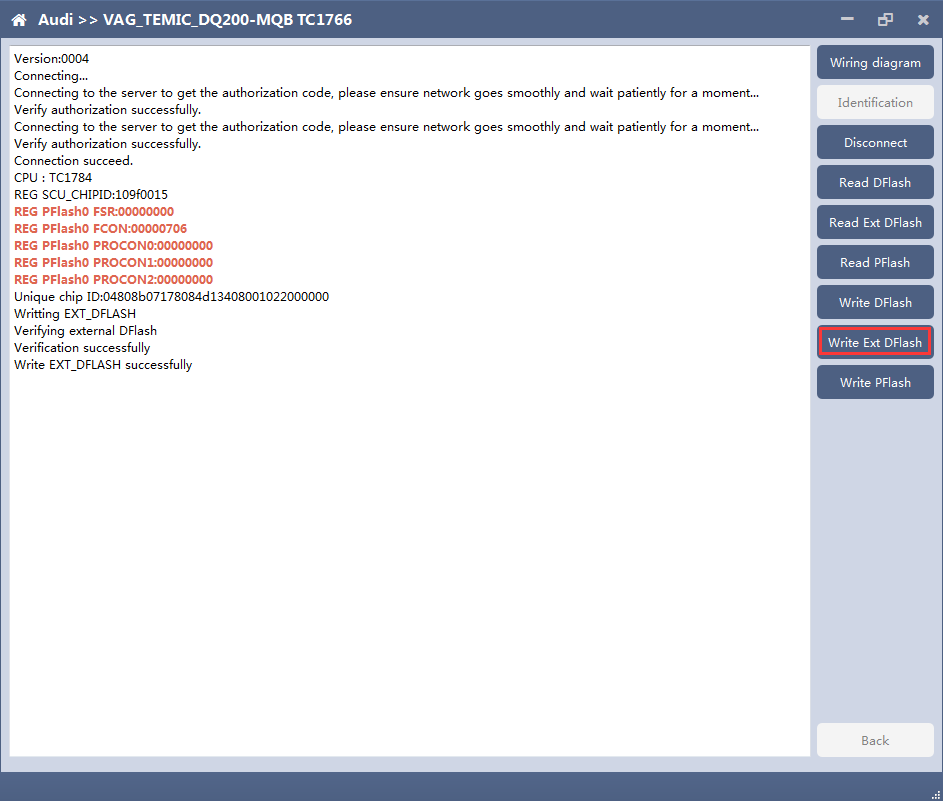

5. Write DFlash. EXT DFlash and PFlash

Take writing EXT-DFlash as an example:

Back up original data before writing flash.

Please note:In the process of writing data, it is strictly forbidden to disconnect the power supply or the connection of the device; if the software is shut down or the computer is shut down or crashes unexpectedly in the process of writing data, please do not disconnect the power supply or the connection of the device, and keep it for 15 minutes, the device can complete the data recovery independently.

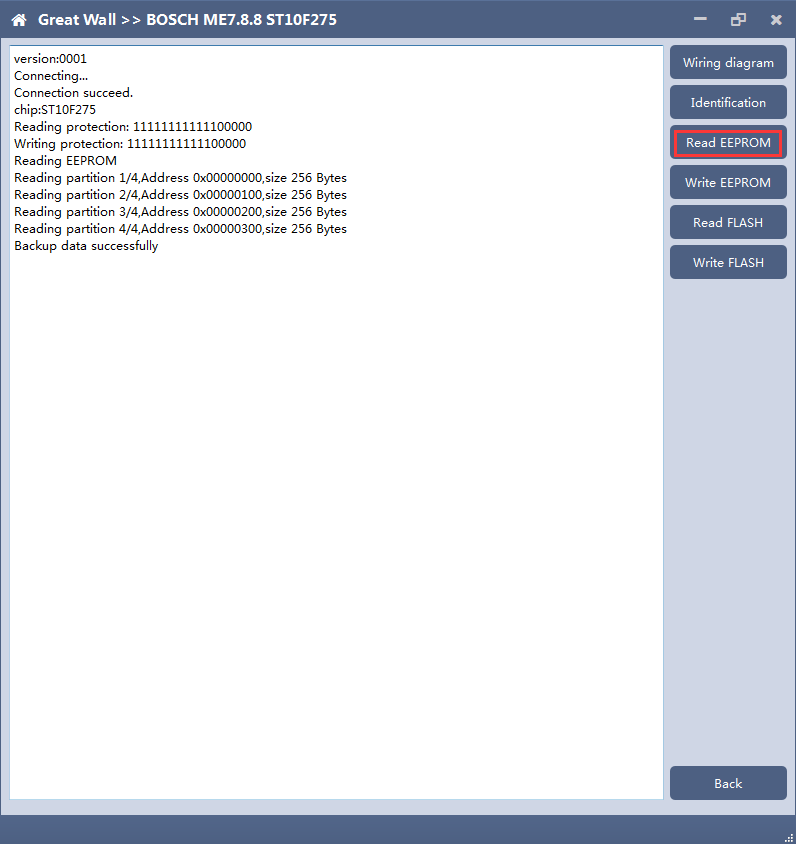

8. BOSCH ST10 series(Boot) read and write data

AT-200 currently support ME7.8.8 ECU data reading and writing function.

1. The ECU type should be determined according to car type,and the model should be selected correctly, otherwise it can not operate normally.

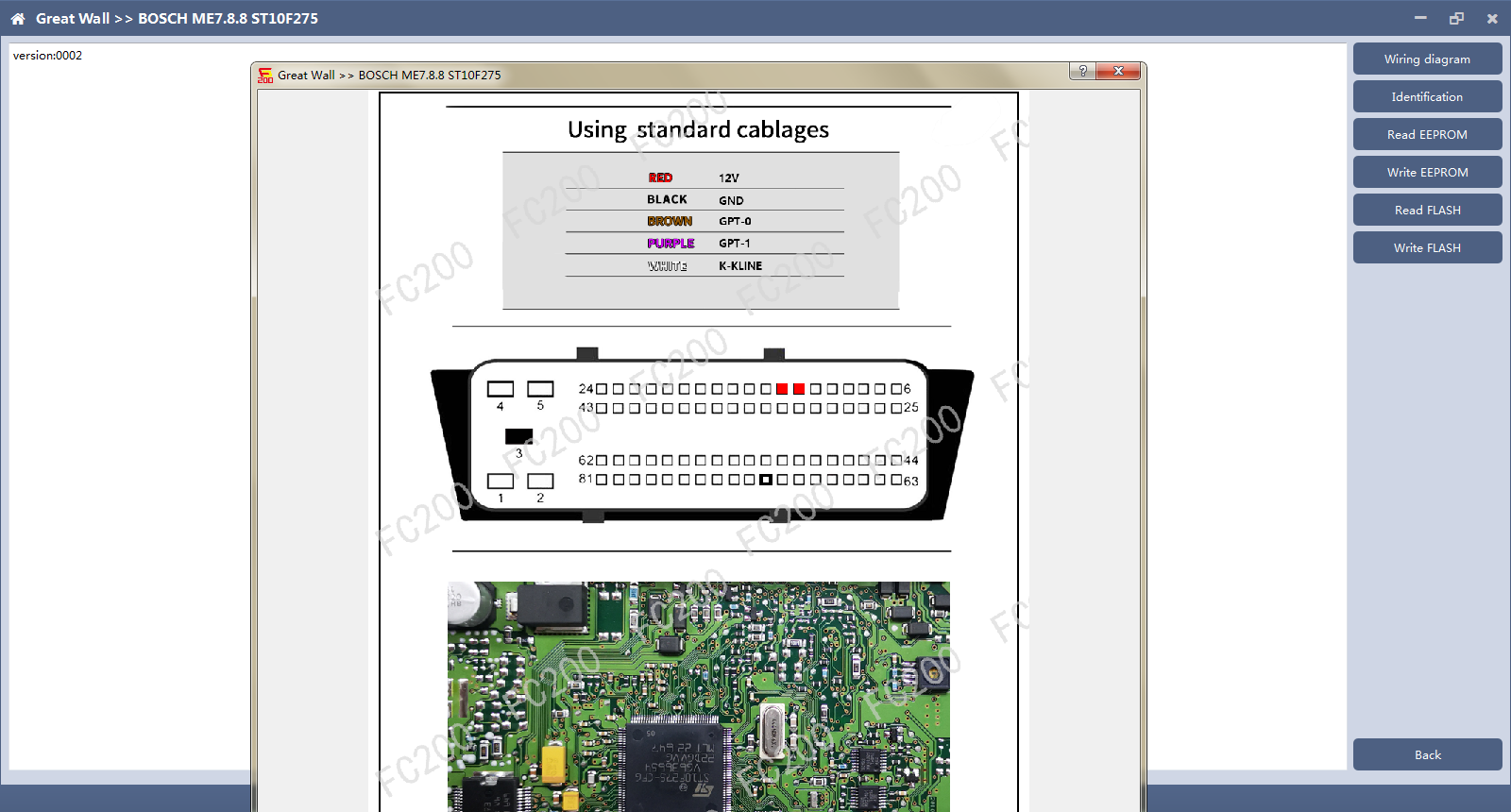

2. Check diagram

Connect the cables according to software diagram.

Note:Password reading is the password reading connection, and bootloader reading is the boot mode connection.

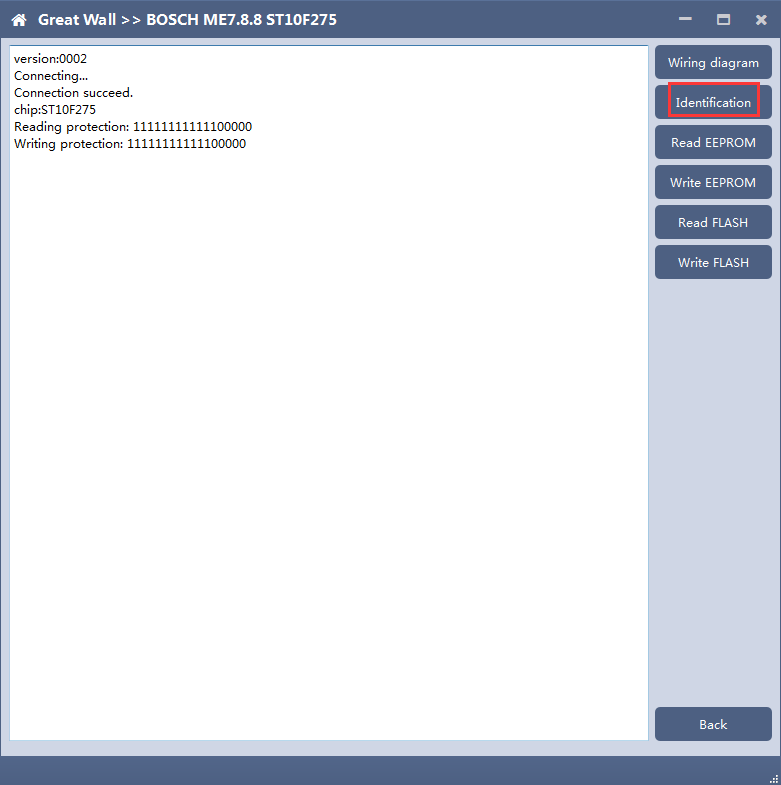

3 Identification

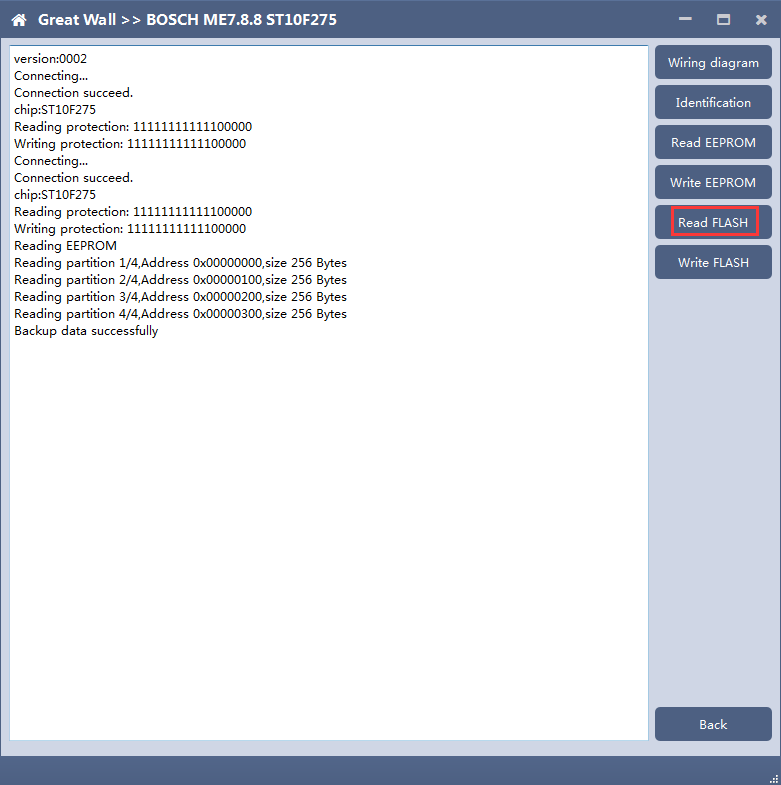

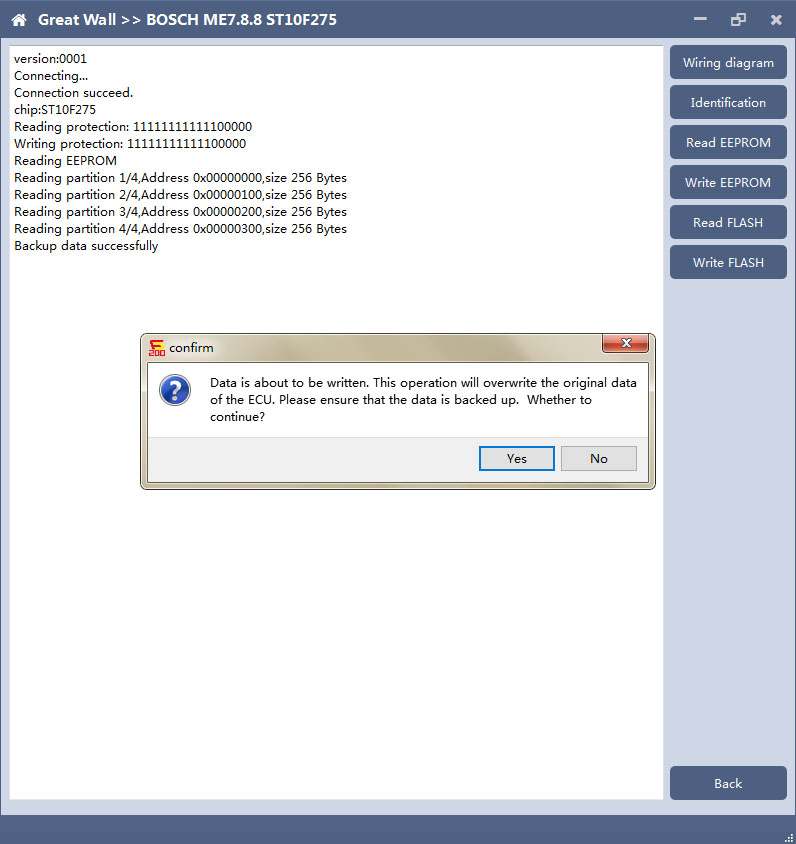

4. Read EEPROM and FLASH

5. Write EEPROM and FLASH

Please read the backup data before writing

Note: in the process of writing data, it is strictly forbidden to disconnect the power supply or the connection of the device; if the software is shut down or the computer is shut down or crashes unexpectedly in the process of writing data, please do not disconnect the power supply or the connection of the device, and keep it for 15 minutes. The device can recover the data independently.

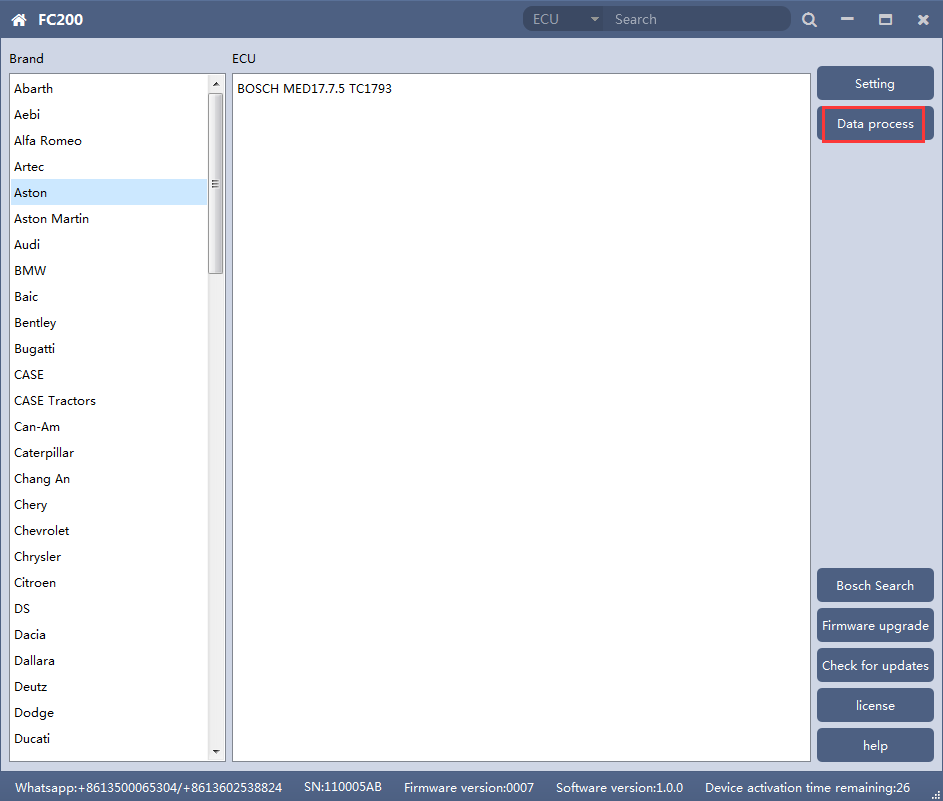

9. MED17/EDC17 data process tool

FC200 currently support(Generation 4 and 5 anti theft of AUDI/SEAT/SKODA/VOLKSWAGEN)ECU data parsing and modification.

Support Bosch MED/EDC17series immo off.

Support the closing TPROT function of Bosch VAG MEDC17 series, BMW / mini MEVD17 / EDC17 series, Hyundai / Kia EDC17 & MED (G) 17 series.

1. Choose AUDI/SEAT/SKODA/VOLKSWAGEN car type then enter data process function

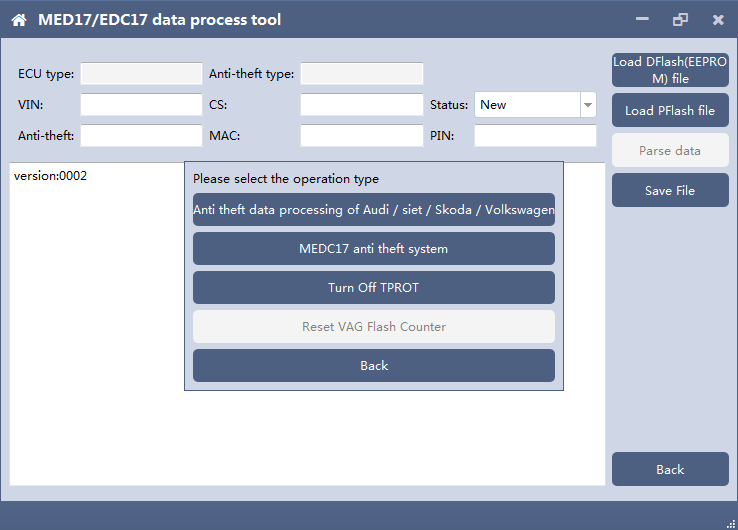

2. Select operation type

Choose function need to be operated

3. AUDI/SEAT/SKODA/VOLKSWAGEN anti-thief data process function

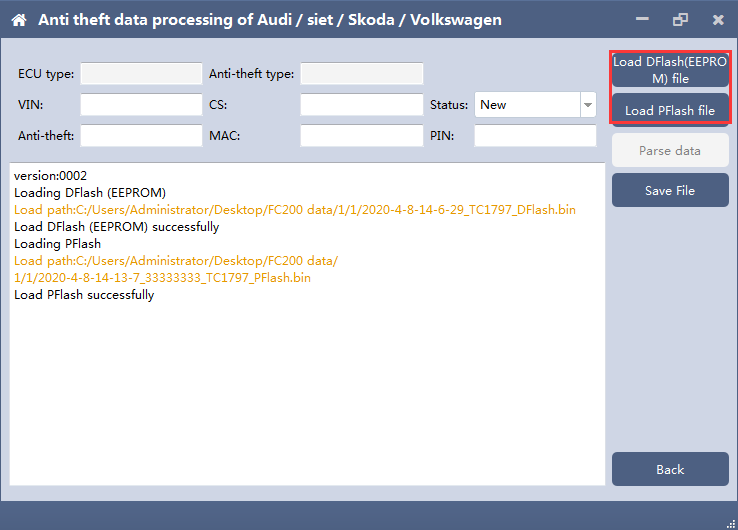

3.1 Load DFlash(EEPROM) and PFlash files

Load DFlash (EEPROM) and PFlash files respectively

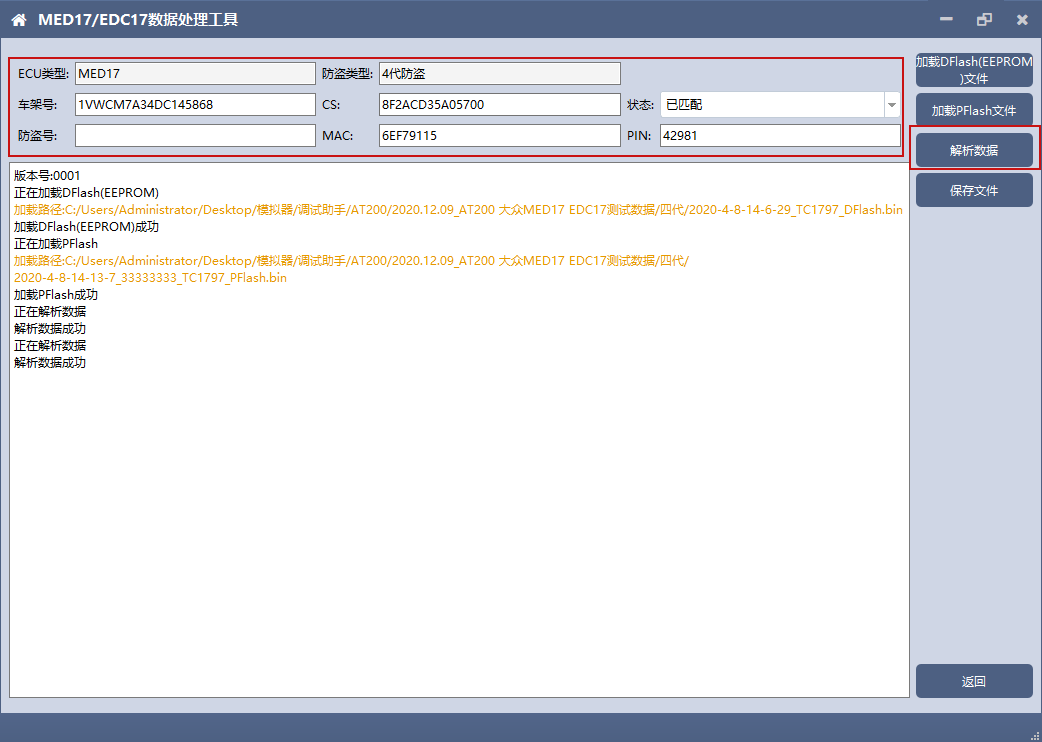

3.2 Parsing data

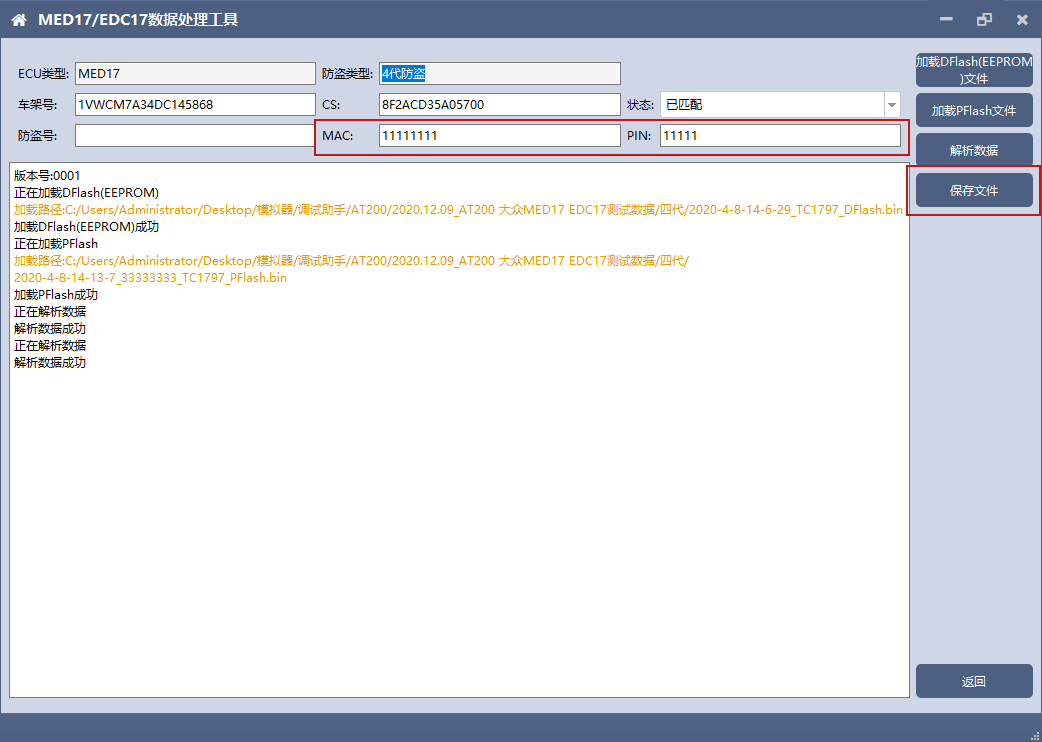

3.3 Modify the data and save the file

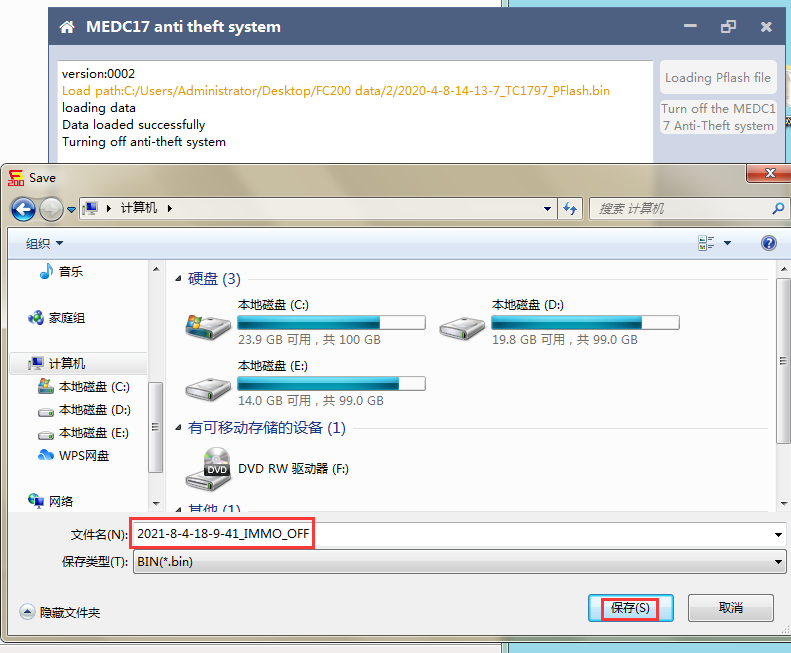

4. MEDC17 anti-theft system function

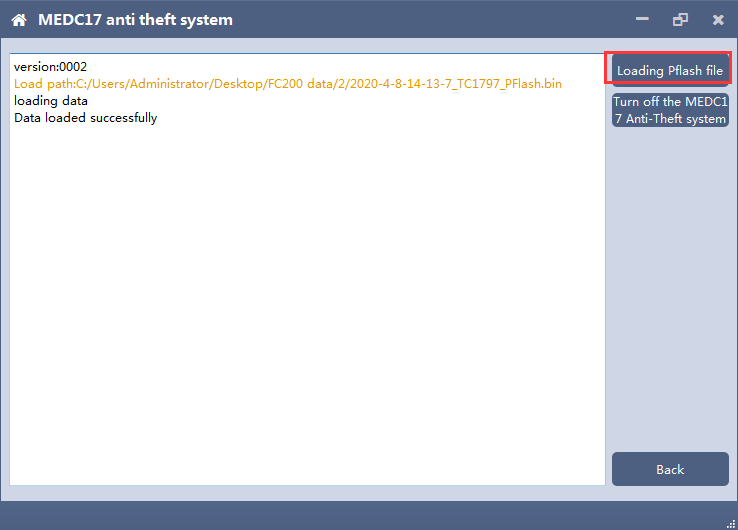

4.1 Load PFLASH data

4.2 Turn off the MEDC17 anti-theft system and save file

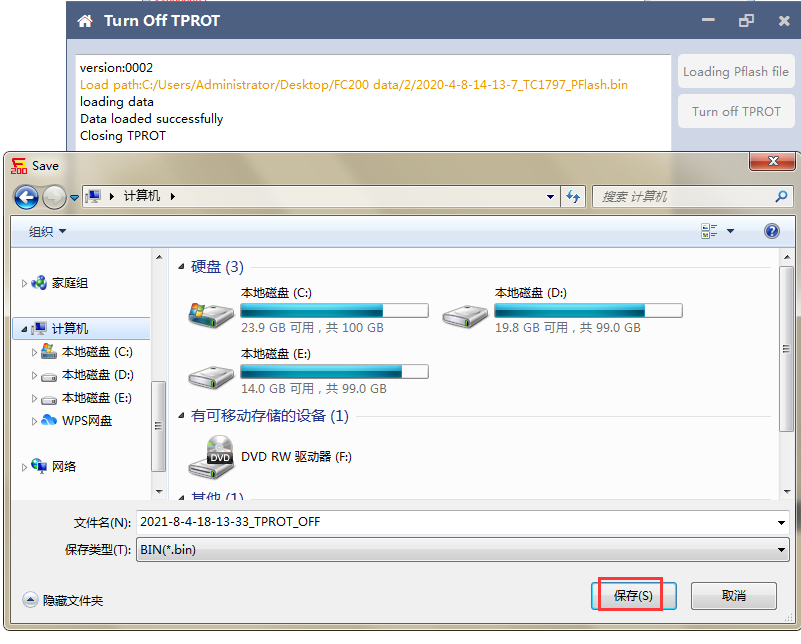

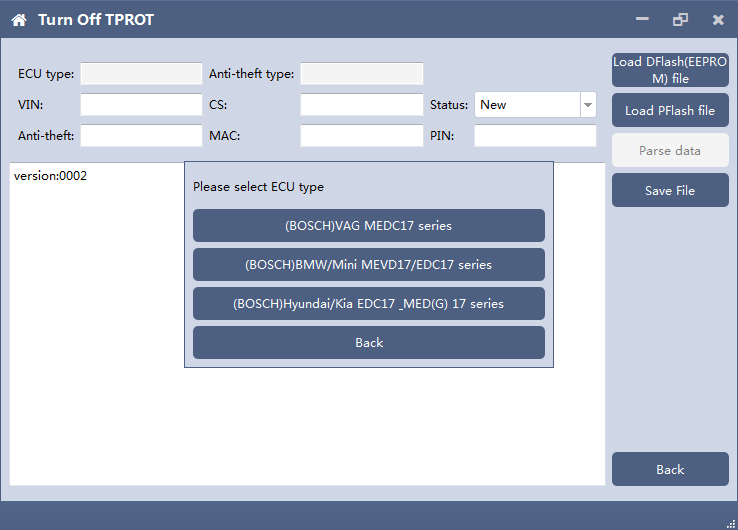

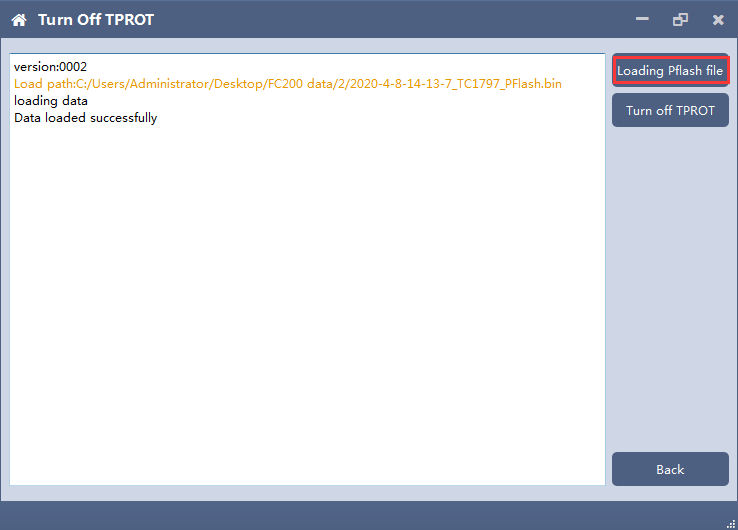

5. Close TPROT

5.1 Select ECU type

Choose correct ECU type, currently support the Bosch VAG MEDC17 series, BMW / mini MEVD17 / EDC17 series, Hyundai / Kia EDC17 & MED (G) 17 series .

5.2 Load PFLASH data

5.3 Close TPROT and save the file.