BMW ICOM Updated the new software to 2022.03

Dear friends, goods news ,BMW ICOM updated the new software to 2022.03. V2022.03 BMW ICOM Engineers Software HDD For BMW ICOM Next BMW ICOM A2 A3 Diagnosis […]

Dear friends, goods news ,BMW ICOM updated the new software to 2022.03. V2022.03 BMW ICOM Engineers Software HDD For BMW ICOM Next BMW ICOM A2 A3 Diagnosis […]

BMW ICOM NEXT Latest Generation Diagnostic Head For BMW, MINI, Rolls-Royce BMW-Model. Can Replace BMW ICOM A2, including all function of ICOM A2. BMW ICOM […]

VXDIAG VCX SE for BENZ C6,BMW ICOM,JLR ,VAS ,HONDA ,TOYOTA,PIWIS,Subaru,VOLVO,GM,Ford,MAZ Auto diagnostic tool Note: The hard drive comes with MB STAR C6 DoIP,BMW ICOM, GM […]

Recently, I’ve purchased original ICOM Next interface, subscribed to BMW on line service and installed ISTA v.29. All works OK when I connect the Icom […]

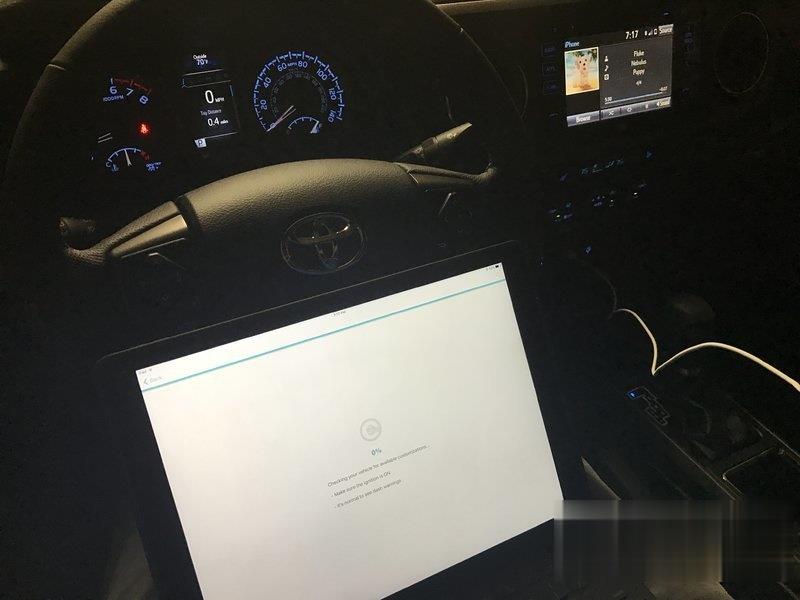

Review 1: Have Tech Stream, not used Carista Tech Stream software is free. The cable is about 15usd. For the Tech Stream software free download […]

OD6 DoIP VCI J2534/DoIP OE diagnostic tool for Jaguar,rover,BENZ, BMW,VW, HONDA, TOYOTA Multiple in one OD6 DoIP VCI multi in one DoIP OE diagnosis is a […]

This ICOM is the head that connects to a vehicle’s OBD connection and communicates over the network to your diagnosis and programming computer. … Specifically […]

What is BMW E-sys? BMW E-sys is a BMW coding software application distributed by BMW Group for BMW F series coding.And with BMW E-sys software […]

Purpose: To see the BMW Diagnostic Tool options is working or not, on 525i with an engine N53. Diagnostic tool: BMW ICOM A2/ICOM Next with ISTA […]

Hello mates. I do not know what to choose between BMW ICOM A3 HW 1.38 and BMW ICOM NEXT A + B + C HW […]

Copyright © 2025 | WordPress Theme by MH Themes